Aerospace

Innovative aerospace industry foam solutions

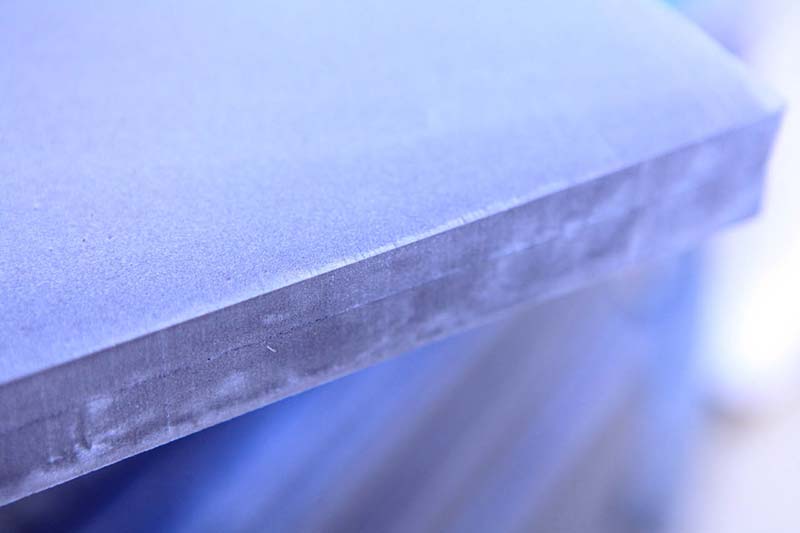

Kewell Converters proudly collaborates with esteemed partners such as ZOTEK and PLASTAZOTE, integrating their products into a myriad of applications tailored for the aerospace industry. These foams are distinguished by their minimal water vapour permeability, low water absorption, and commendable insulation and wear performance, ensuring longevity and adaptability during the manufacturing process.

Key foam products for aerospace

Advanced foams

Traditional foams like Silicone and PVC Nitrile often fall short in meeting specific aerospace standards. In contrast, ZOTEK’s closed-cell structure and PLASTAZOTE foams excel in these domains, ensuring optimal performance and safety.

Request a quote

Crafting components with advanced foams

Kewell Converters specialises in crafting components using these advanced foams. Our state-of-the-art facility is equipped to laminate, die-cut, weld, rout, and saw, ensuring we meet the rigorous standards of the aerospace industry. Over the years, we’ve successfully delivered foam components for seating, insulation, crash pads, headrests, and other critical aircraft applications.

Aerospace materials & components overview

Kewell Converters remains committed to delivering excellence, ensuring that aerospace professionals and engineers have access to the finest foam solutions available.

Civil, business, and military aviation

AZOTE, especially PLASTAZOTE and ZOTEK F foams, are extensively utilised due to their closed-cell structure. Learn more about Zotefoams.

Cabin interiors

PLASTAZOTE foam is optimal for seating and soft trim areas.

Galley application

Our foams find utility in the aircraft’s galley area.

Airframe utilisation

ZOTEK F and PLASTAZOTE foams are integral for acoustic and thermal insulation. Learn more about Zotefoams.

Packaging applications

AZOTE foams have long been the preferred packaging material in the aviation sector. Learn more about Zotefoams.

Military applications

The lightweight and energy-absorbing properties of our foams are perfect for military aircraft applications.

FAQs

Traditional foams like Silicone and PVC Nitrile often fall short in meeting specific aerospace standards, particularly in terms of weight, water absorption, and radiant panel test requirements. ZOTEK and PLASTAZOTE foams excel in these domains due to their closed-cell structure, minimal water vapour permeability, and commendable insulation and wear performance.

Our state-of-the-art facility is equipped to laminate, die-cut, weld, rout, and saw, ensuring we meet the rigorous standards of the aerospace industry. We specialise in crafting components using advanced foams, delivering solutions for seating, insulation, crash pads, headrests, and other critical aircraft applications.