Machine Capabilities

At Kewell Converters, our proficiency lies in designing and producing bespoke foam products tailored to your unique requirements. With an unwavering dedication to precision and quality, our manufacturing expertise combines time-honoured techniques with state-of-the-art foam fabrication methods and an expansive range of machine capabilities.

In-House Manufacturing Excellence

Our manufacturing prowess resides under a single roof, boasting an expansive range of advanced foam fabrication equipment and specialised CNC machinery. By harnessing numerous lean-manufacturing techniques, we’ve cultivated a dynamic and streamlined production environment that promises swift turnaround times.

Our manufacturing processes are strategically designed to not only align with individual customer specifications but also to be cost-effective. Moreover, our commitment to minimising waste and maximising yields exemplifies our environmentally conscious approach.

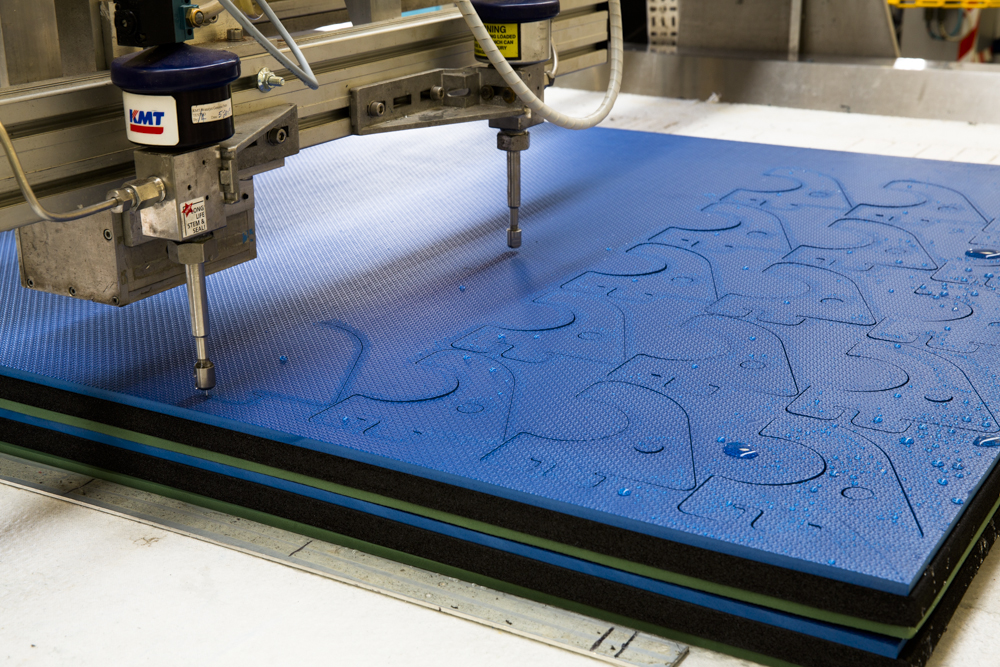

CNC Water-Jet Cutting

Unleash unparalleled precision with Kewell Converters’ CNC Water-Jet Cutting. Achieve immaculate edges and intricate designs effortlessly. Dive into the world of high-pressure precision, where water meets technology. Kewell Converters—combining the force of nature with cutting-edge innovation.

Primary Fabrication & Cutting

- Strip Cutting & Band Sawing (including Automatic)

- Horizontal Cutting / Splitting (Slitting)

- Tube & Cord Profiling (Forming)

- Precision Press/Die Cutting

- Wire and Hot Blade Cutting

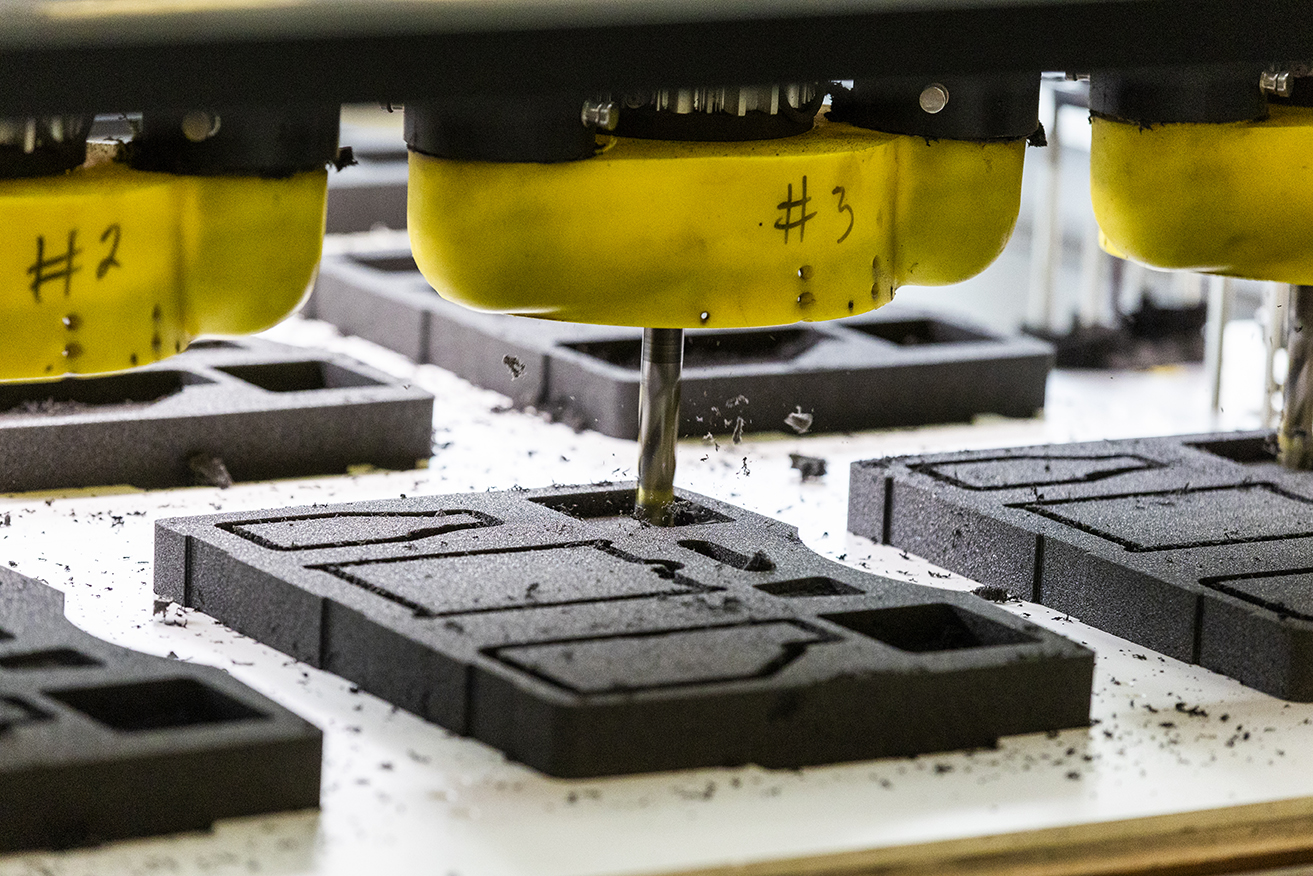

Precision Press/Die Cutting

Master the art of exactitude with Kewell Converters’ Precision Press/Die Cutting. Delivering clean cuts and sharp details every time. Embrace the synergy of power and precision in every press. Kewell Converters—where craftsmanship meets state-of-the-art technology.

CNC Vertical Contour Cutting

Experience precision with Kewell Converters’ CNC Vertical Contour Cutting. Elevate your projects with unmatched accuracy and seamless finishing. Harness the power of advanced CNC technology tailored for intricate contours. Kewell Converters—where innovation meets precision.

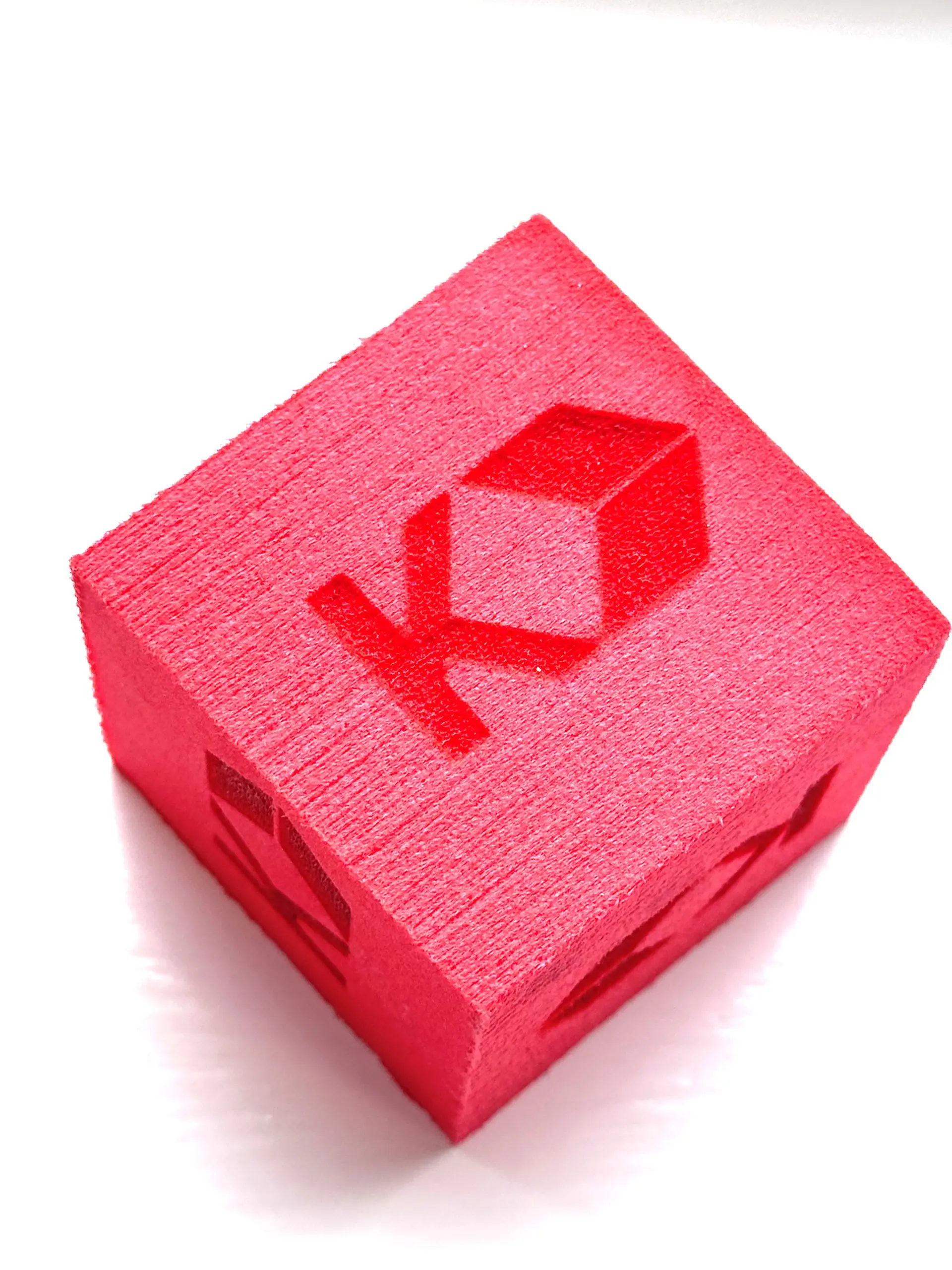

Unveil Precision with Laser Engraving

At Kewell Converters, we’re taking foam fabrication to the next level with our cutting-edge laser engraving services. Tailored to meet the demands of a wide array of industries, including retail, our service stands out by offering branding, part marking, and the creation of intricate CNC-cut parts with unmatched precision and personalisation. Read more here.

Other Production Services

- Sub-Contract Manufacturing

- Assembly & Packaging Solutions

- Self-Adhesive Backing (SAB) Application

- Comprehensive & Custom Fabrication

- Full Product Design & 2D/3D CAD/CNC Programming (AutoCAD, Mastercam and SpaceClaim)