EPDM & Neoprene

Specialised foam materials engineered for extreme environments in defence, aerospace, and industrial sectors

At Kewell Converters, we’ve spent over 50 years developing high-quality foam solutions for demanding applications. Our bespoke foam conversion expertise, combined with a deep understanding of specialised foam materials like EPDM and neoprene, allows us to solve complex engineering challenges with precision, efficiency, and durability.

Whether you need high-performance gaskets, seals, protective foam inserts, or highly customised foam parts, Kewell Converters has the materials knowledge, design experience, and manufacturing capabilities to deliver consistently high-quality results.

Why EPDM & neoprene foam?

Both EPDM rubber foams and neoprene foams are durable, flexible, and highly resistant to harsh environmental conditions, making them the preferred choice for mission-critical applications.

Key benefits of EPDM foam:

- Exceptional weather and ozone resistance: ideal for long-term outdoor use, resisting UV, rain, and temperature extremes

- Water and chemical resistance: acts as a durable seal or barrier, even in harsh environments

- Flame-retardant options: available in UL94 and M1/F1 rated formats for use in fire-sensitive sectors

- Custom formats: supplied as sheets, rolls, or fabricated into foam shapes and components to meet exact specifications

- Self-adhesive options: enhances ease of installation in production environments

Key benefits of neoprene foam:

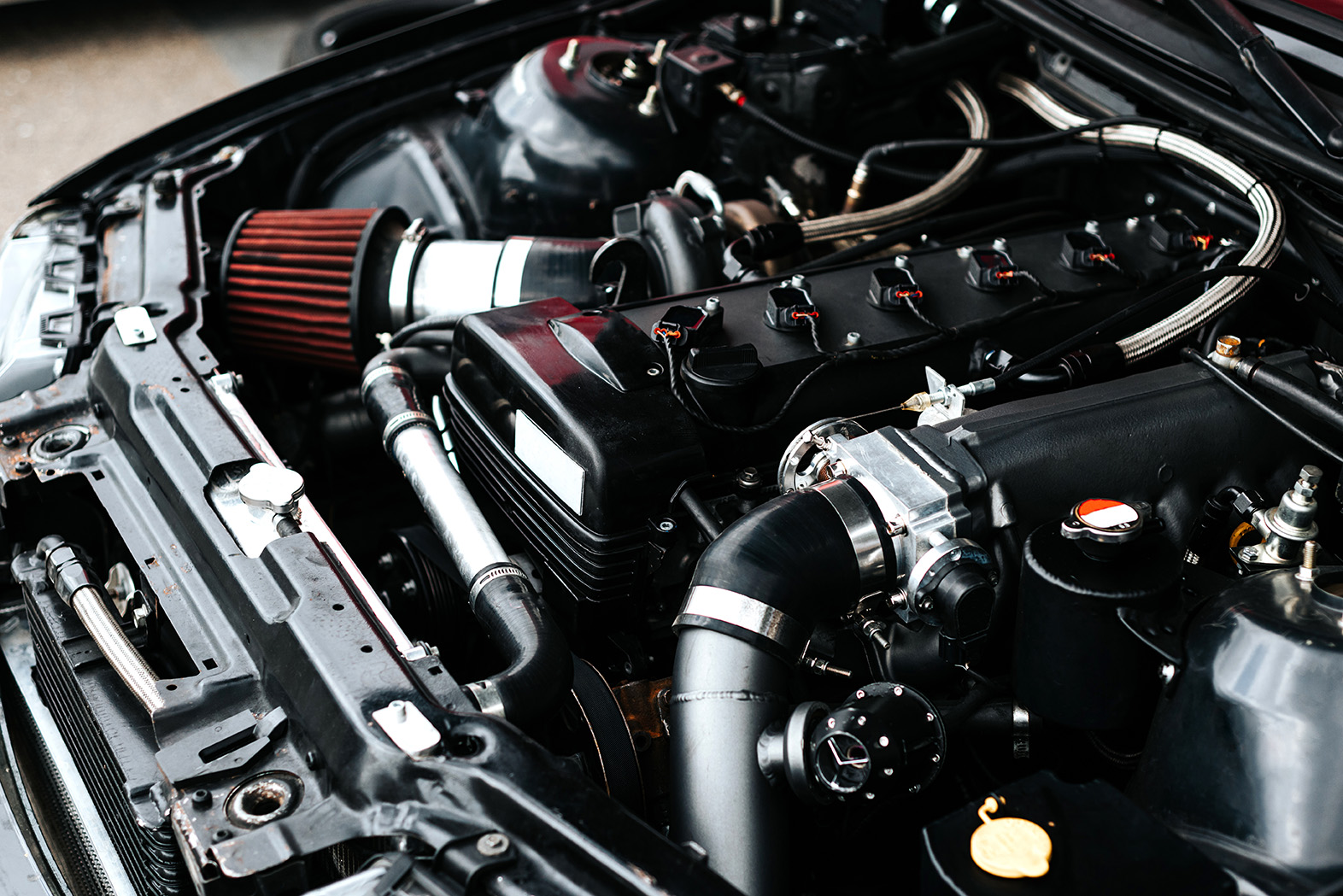

- Superior vibration dampening: absorbs shocks and reduces noise—perfect for aerospace, automotive, and defence applications

- Broad temperature tolerance: remains stable and flexible from -40°C to +100°C and beyond

- Oil and solvent resistance: suitable for applications involving contact with fuels, lubricants, and industrial chemicals

- Compression recovery: maintains shape and sealing properties under pressure and repeated use

- Lightweight yet tough: easy to handle without compromising on performance or protection

Bespoke foam conversion for high-performance applications

At Kewell Converters our foam fabrication process includes full CAD design, prototyping, CNC routing, and precision machining to ensure every component is optimised for its end-use. Whether you’re working on a defence-grade protective case insert, a flight-certified panel seal, or an environmental barrier for electronics, we adapt the foam to fit your exact needs.

We regularly produce:

- Protective foam inserts for sensitive equipment during transit

- Sealing gaskets and foam strips for enclosures exposed to weather and chemicals

- Vibration damping pads for mechanical and aerospace systems

- Custom foam shapes for interior panels, control units, or packaging

- High-performance foam parts for integration into larger assemblies

A smarter supply chain starts here

As specialists in bespoke foam solutions, we’ve evolved our offering to better support your team. More of our clients now rely on Kewell Converters to manage part of the supply chain, from sourcing the right foam materials, designing the solution, to liaising with other suppliers and manufacturing complete foam components.

This reduces your workload, minimises supplier risk, and improves lead times—all while ensuring your foam parts are delivered exactly as required, with no compromise on quality.

Proven expertise across critical sectors

Our EPDM and neoprene foam solutions are already trusted in sectors where reliability and compliance are non-negotiablec

Military and defence

Tactical gear cases, vehicle seals, insulation for communication equipment

Aerospace

Flight-safe gaskets, vibration isolators, protective packaging for instruments

Industrial & manufacturing

Weatherproofing, sound insulation, cushioning for precision tools

Electronics & HVAC

Enclosure seals, temperature insulation, cable management inserts

Let's solve your foam challenge

If you need a trusted foam fabricator for your next project—or a partner who can guide you from concept through to production—Kewell Converters is here to help. We develop bespoke foam solutions that solve real problems and add value to your product.

FAQs

They’re ideal for gaskets, seals, vibration dampening, weatherproofing, and protective inserts in defence, aerospace, and industrial systems.

EPDM foam offers excellent resistance to UV, ozone, moisture, and temperature extremes—making it perfect for long-term outdoor applications.

Neoprene foam provides superior shock absorption and compression recovery, making it effective for isolating vibrations in aerospace and automotive applications.

Yes, we supply EPDM and neoprene foams with UL94 and M1/F1 flame-retardant ratings for use in fire-sensitive environments.

Absolutely. We offer self-adhesive options for easier installation and integration into production workflows.