12th June 2025

Production Operator, CNC Team

Read more >

Laser engraving and foam

The Cutting Edge of Foam Customisation using Laser Engraving

In the realm of custom foam fabrication, standing out with precision and personalisation is paramount. That’s why we’ve ushered in a new era of product customisation and precision part fabrication with advanced laser engraving capabilities. The integration of the Wattsan 1610 LT laser machine, equipped with a contour following head, has redefined the standards of foam engraving and cutting, offering vast benefits to a myriad of industries.

Unmatched Precision and Efficiency

Laser engraving isn’t just about marking; it’s the epitome of efficiency, cleanliness, and accuracy in foam product customisation. Laser engraving can deliver flawless etchings at speeds that traditional methods can’t match. This leap in efficiency doesn’t come at the expense of quality. On the contrary, it ensures that every etching is pristine, elevating the aesthetic and functional value of the product.

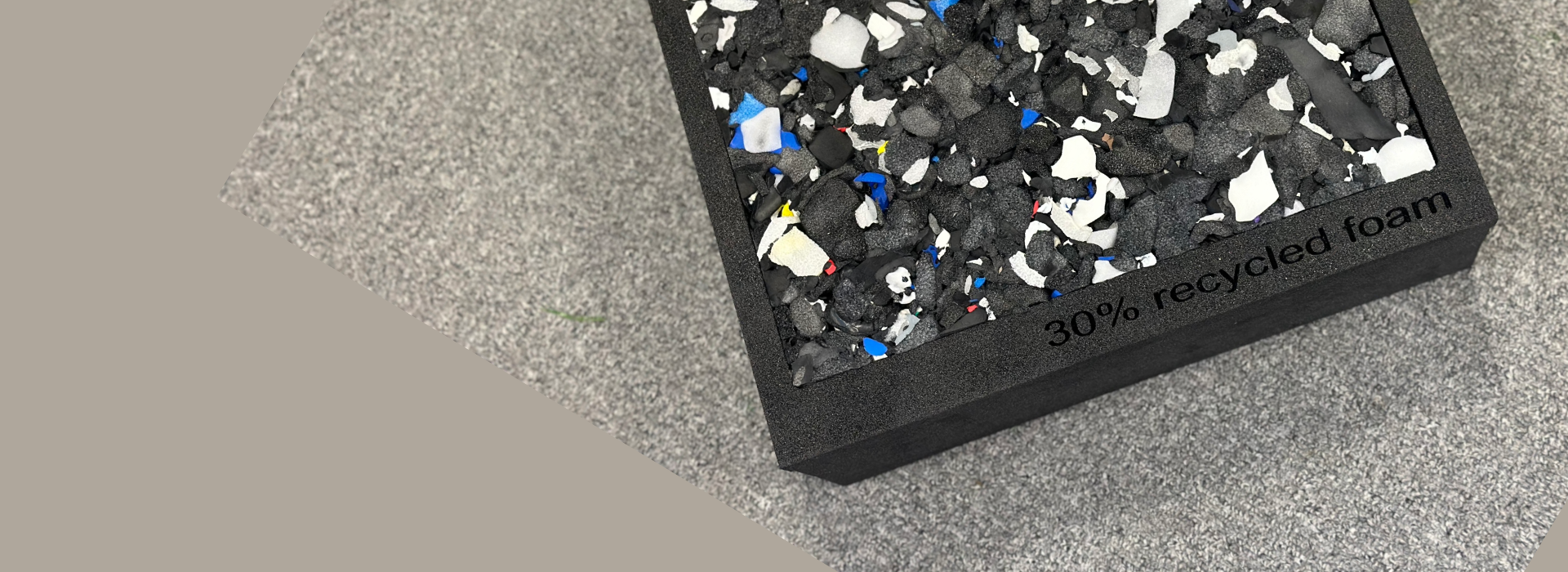

The Materials

Laser engraving can be undertaken on polyethylene foam (LDPE), and polyurethane foam (PUR). These materials are favoured for their cut quality, allowing for clean, fused, and sealed edges that mechanical processes can’t consistently achieve. This capability opens a new world of design and functional possibilities for products requiring precision cuts, markings, and engravings.

Real-World Applications

The versatility of laser engraving is evident in its wide range of applications. From luxurious branding and intricate part marking to the creation of CNC-cut parts, the possibilities are limitless. Industries ranging from engineering and manufacturing to retail and design can benefit from the precision and customisation that laser engraving offers.

The practical applications of laser engraving technology are vast. Case inserts bearing names or descriptions, customer logos on various products, and precision-cut intricate shapes are just the tip of the iceberg. We’ve even engraved logos on high-spec nylon foam parts for sustainable backpacks for the retail industry, showcasing the technology’s adaptability to bespoke projects and sustainability goals.

Enhancing Products

Beyond simple cutting and engraving, we utilise laser marking as an advanced alternative to printing and router engraving. This method is particularly beneficial for products where solvent-based inks could compromise the integrity of the foam or the items it protects. From nametags and company logos to elaborate artwork, laser marking/engraving offers a durable and aesthetically pleasing solution.

The Promise of Precision and Personalisation

Despite the limitations when cutting thicker foams due to heat generation, Kewell Converters’ laser engraving offers a sophisticated alternative to conventional cutting methods like waterjets, bandsaws, presses, and routers. And it can be seamlessly integrated into manufacturing capabilities.

Whether it’s for protective packaging, custom-fit foam inserts, or branded merchandising, Kewell Converters’ laser engraving service is the key to unlocking unparalleled product quality and innovation.

For more information or to discuss your specific project requirements, don’t hesitate to contact us.