Materials

High-performance foam materials engineered for demanding environments

At Kewell Converters, we specialise in foam conversion and foam fabrication for industries where failure isn’t an option. With over 50 years of experience working exclusively with foam, we deliver bespoke foam solutions that meet the rigorous standards of the military, defence, aerospace, and advanced industrial sectors.

We don’t just supply foam—we engineer it. Our experienced in-house engineering team uses full CAD design integration and advanced CNC machinery to design, optimise, and manufacture high-quality foam parts tailored to your exact requirements. Whether you’re looking for bespoke military foam inserts, rugged gaskets and seals, or precision-cut foam shapes, our materials and processes are built to perform in the world’s harshest environments.

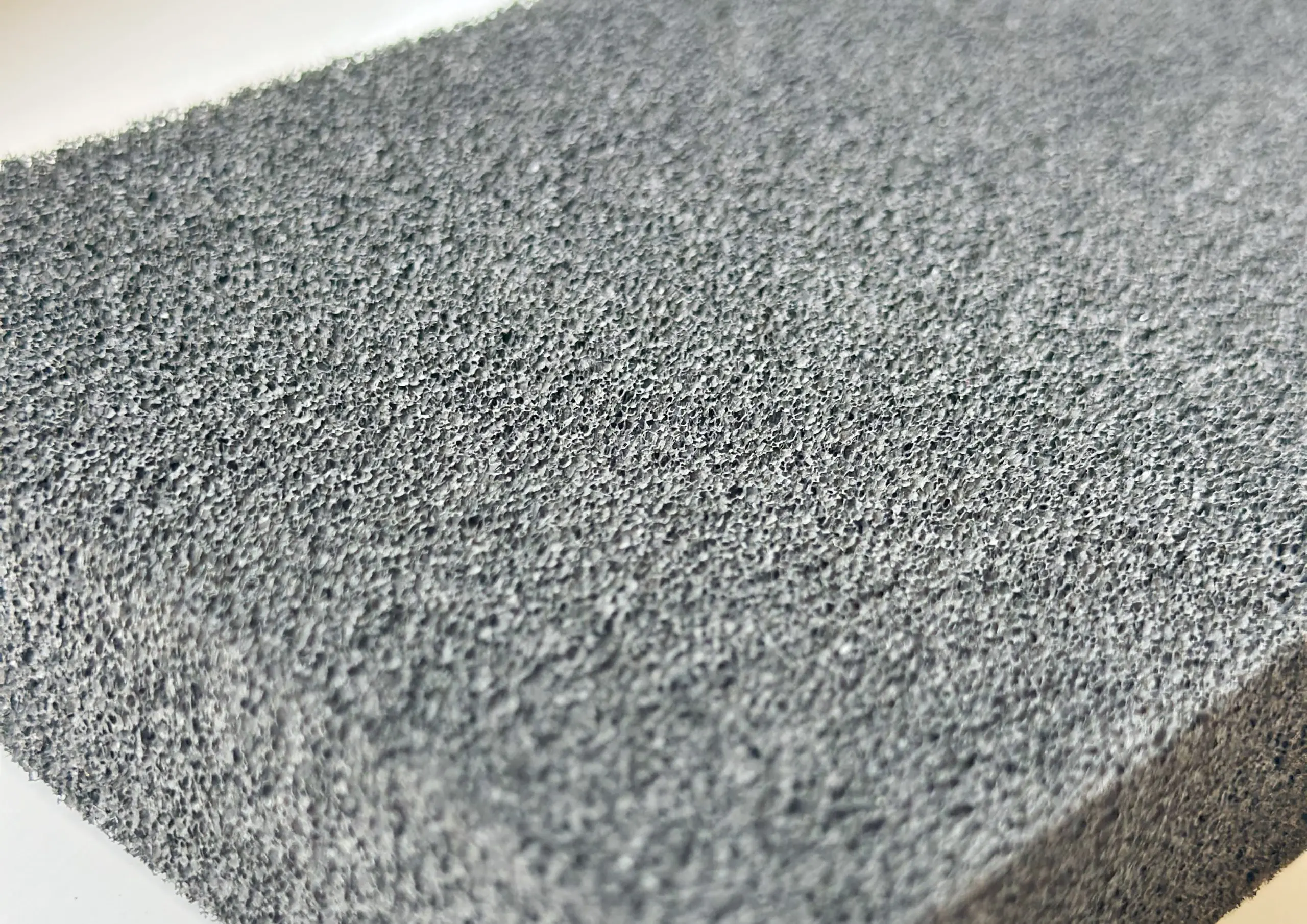

Foam materials that perform under pressure

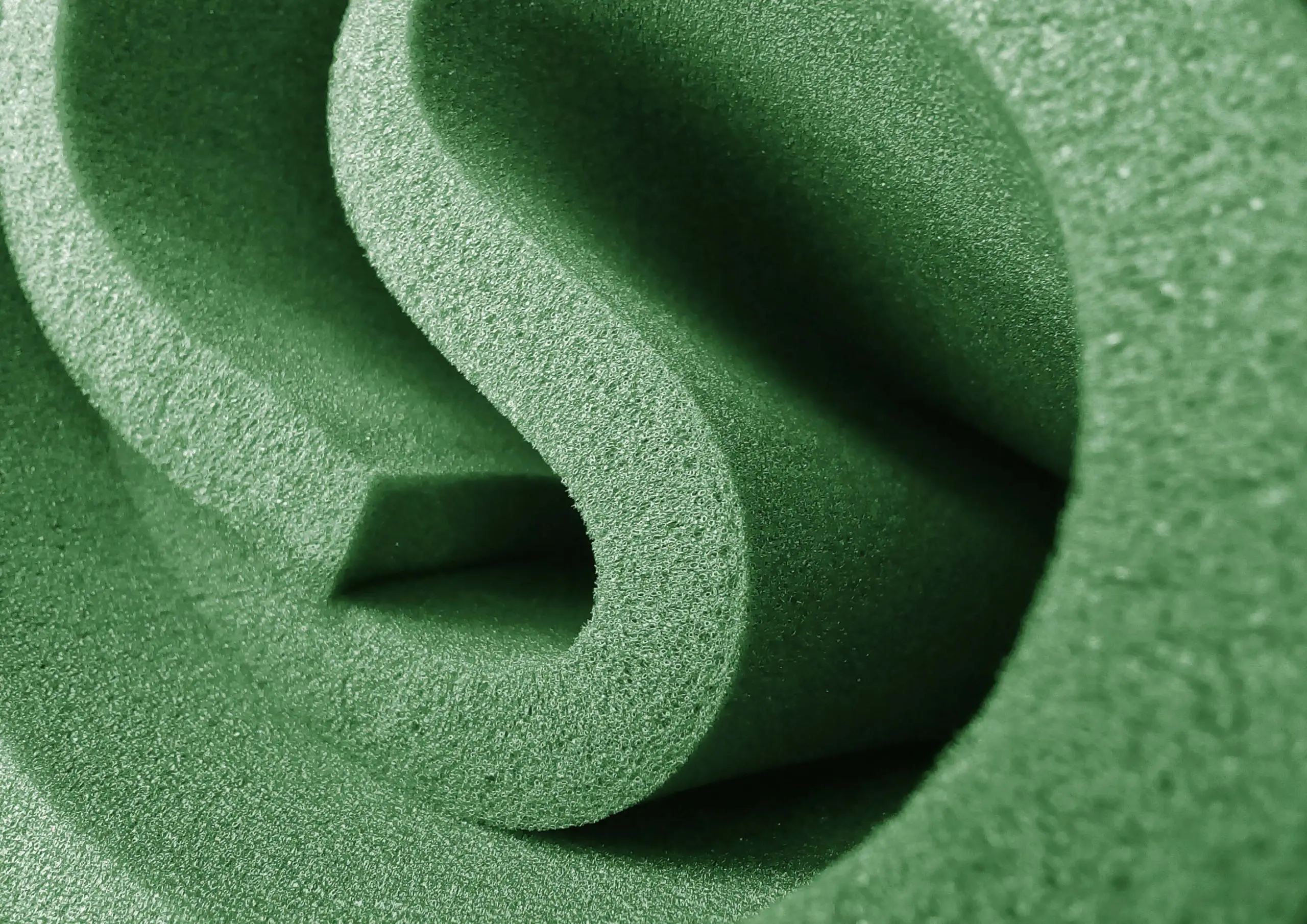

Kewell Converters is a long-standing, accredited foam fabricator and independent distributor of Zotefoams’ world-renowned branded foams, including:

- Azote®: Plastazote®, Evazote®, Supazote® and Ecozote®

- Zotek®: High-performance foams designed for aerospace, automotive and cleanroom environments with fire ratings to meet the toughest applications

These premium branded foams offer excellent durability, lightweight performance, chemical resistance, and thermal insulation—critical in sectors where both safety and reliability are paramount. Our direct supply relationship with Zotefoams ensures consistency, traceability and access to a wide range of specialised foam materials in varying densities, grades, and specifications.

Contact us today to discuss your foam needs

Bespoke foam solutions that add real value

We focus on what we do best—creating bespoke foam solutions that solve complex problems and add measurable value. Our clients trust us to go beyond cutting foam. We design, source, and manage the production of entire assemblies and components, reducing your supply chain complexity and saving your procurement and production teams valuable time and delivering a competitive solution.

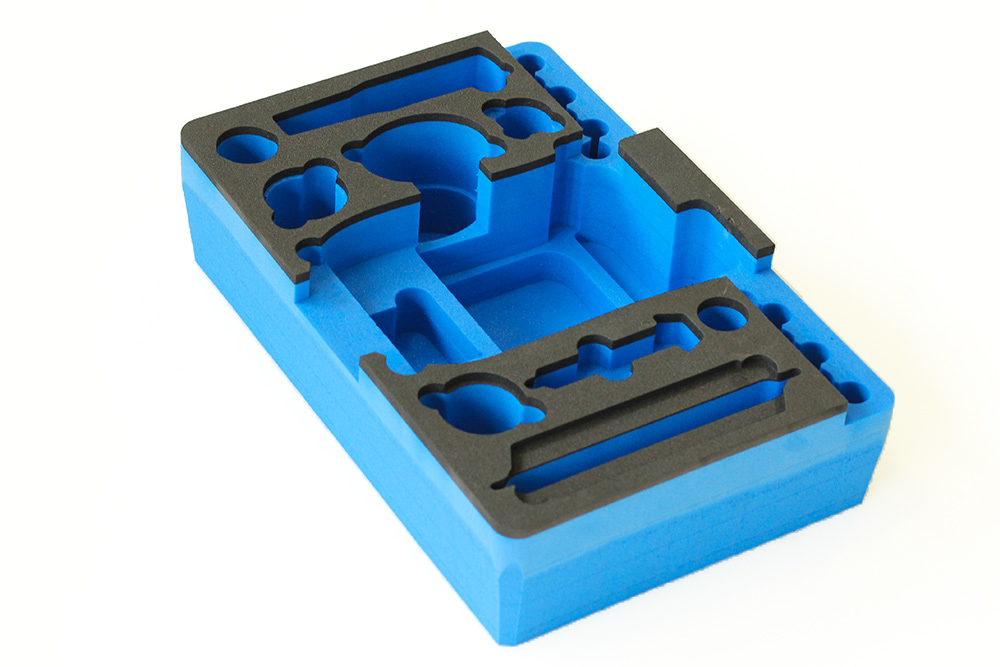

Design-efficient custom foam parts

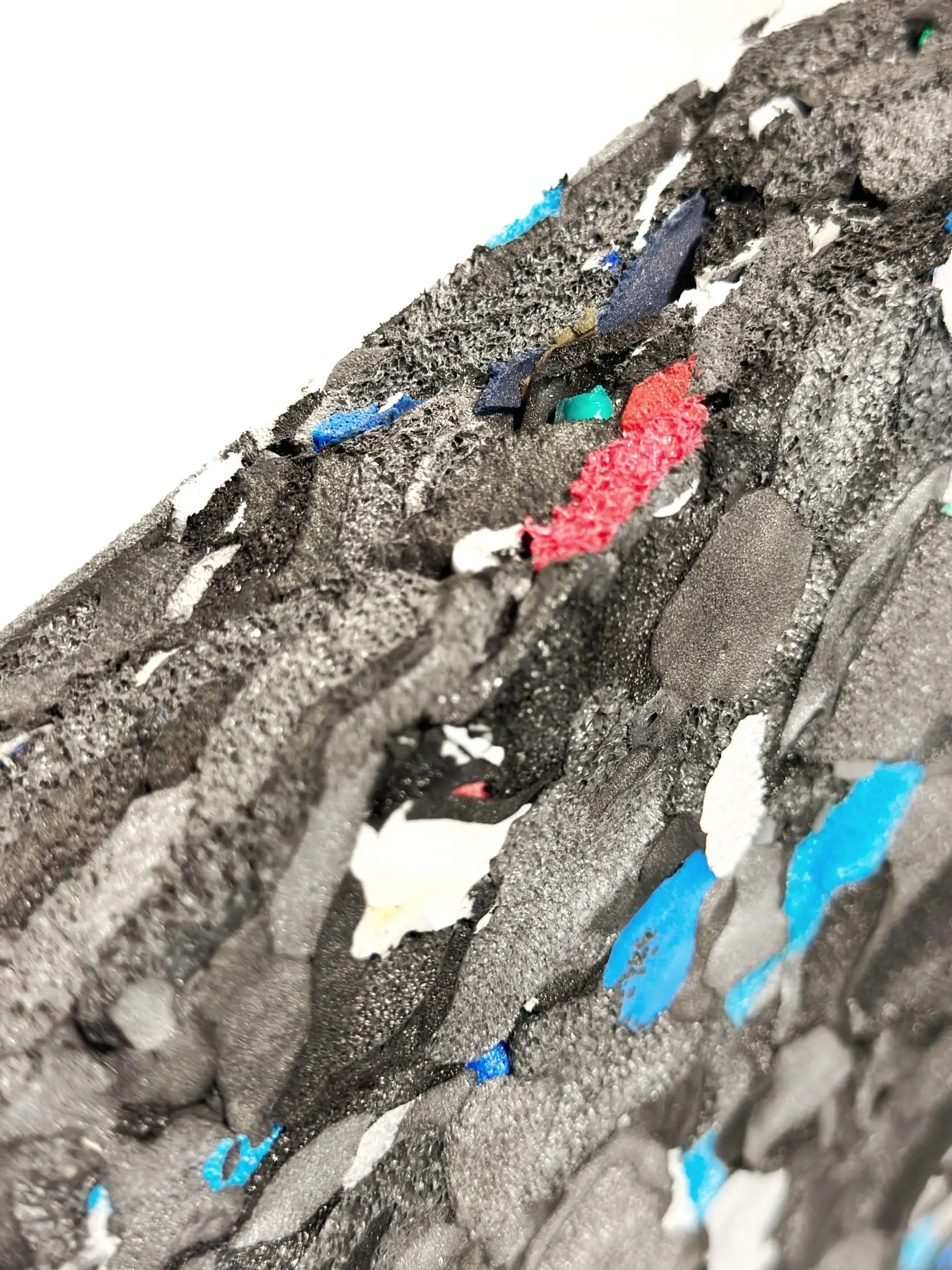

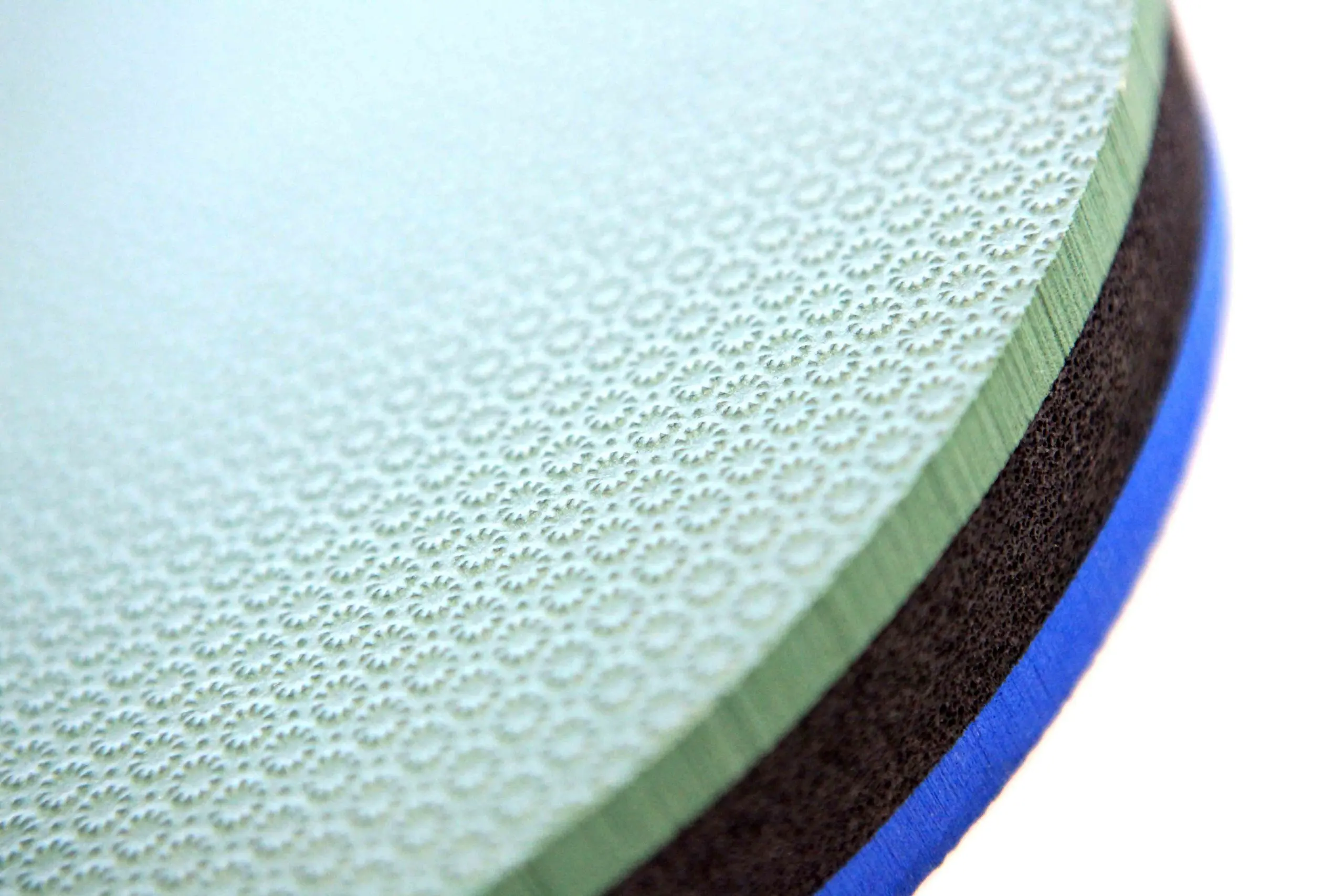

Composite foam assemblies

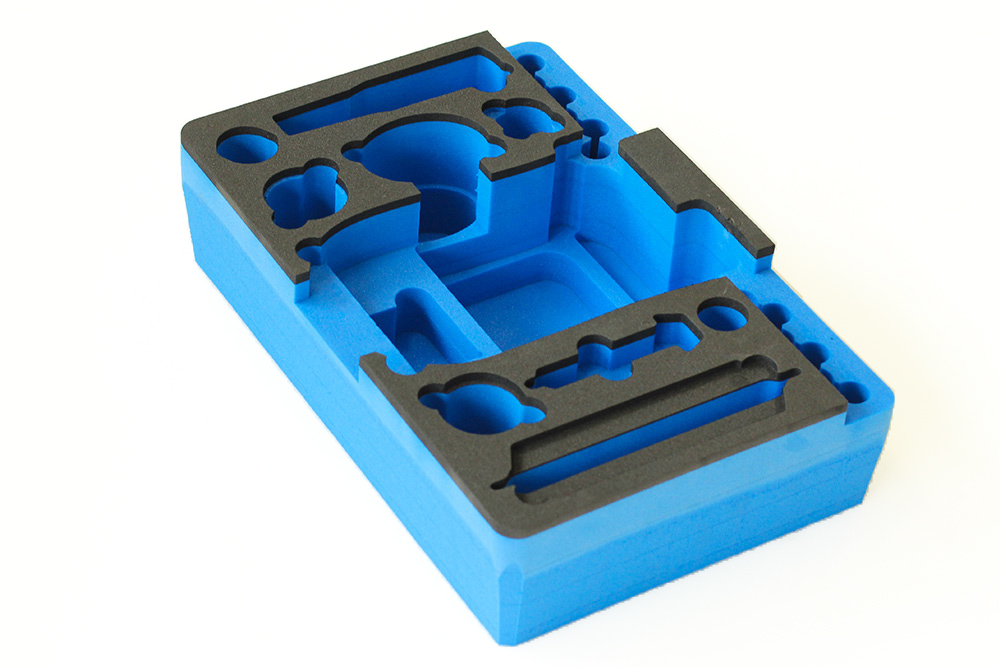

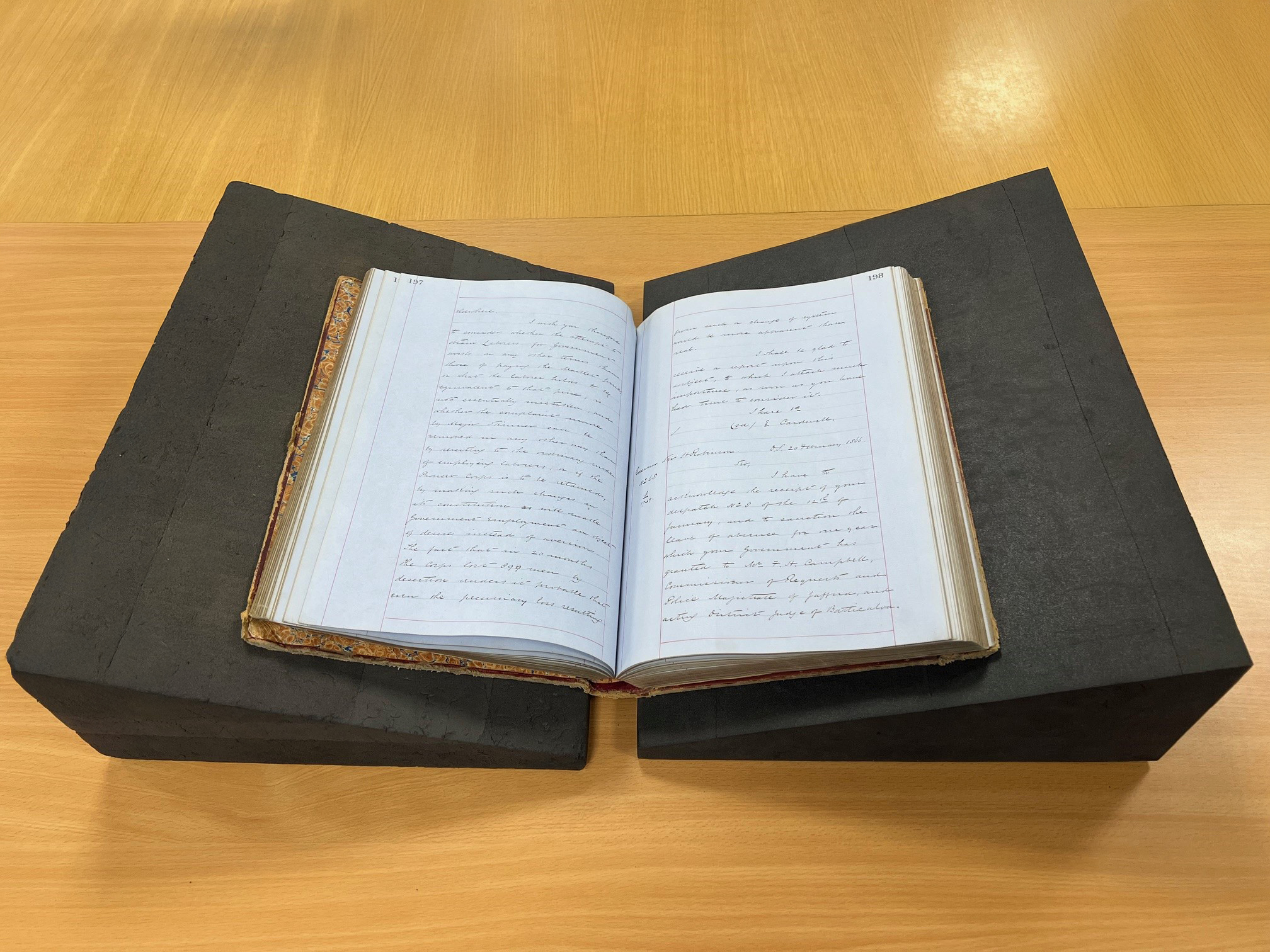

Advanced foam inserts

for transit cases, tooling, and instrumentation

Military-grade foam packaging

that meets strict MOD and NATO standards

Thermoforming and CNC

for precision and repeatability

Materials by use

Product Protection & Transit Packaging

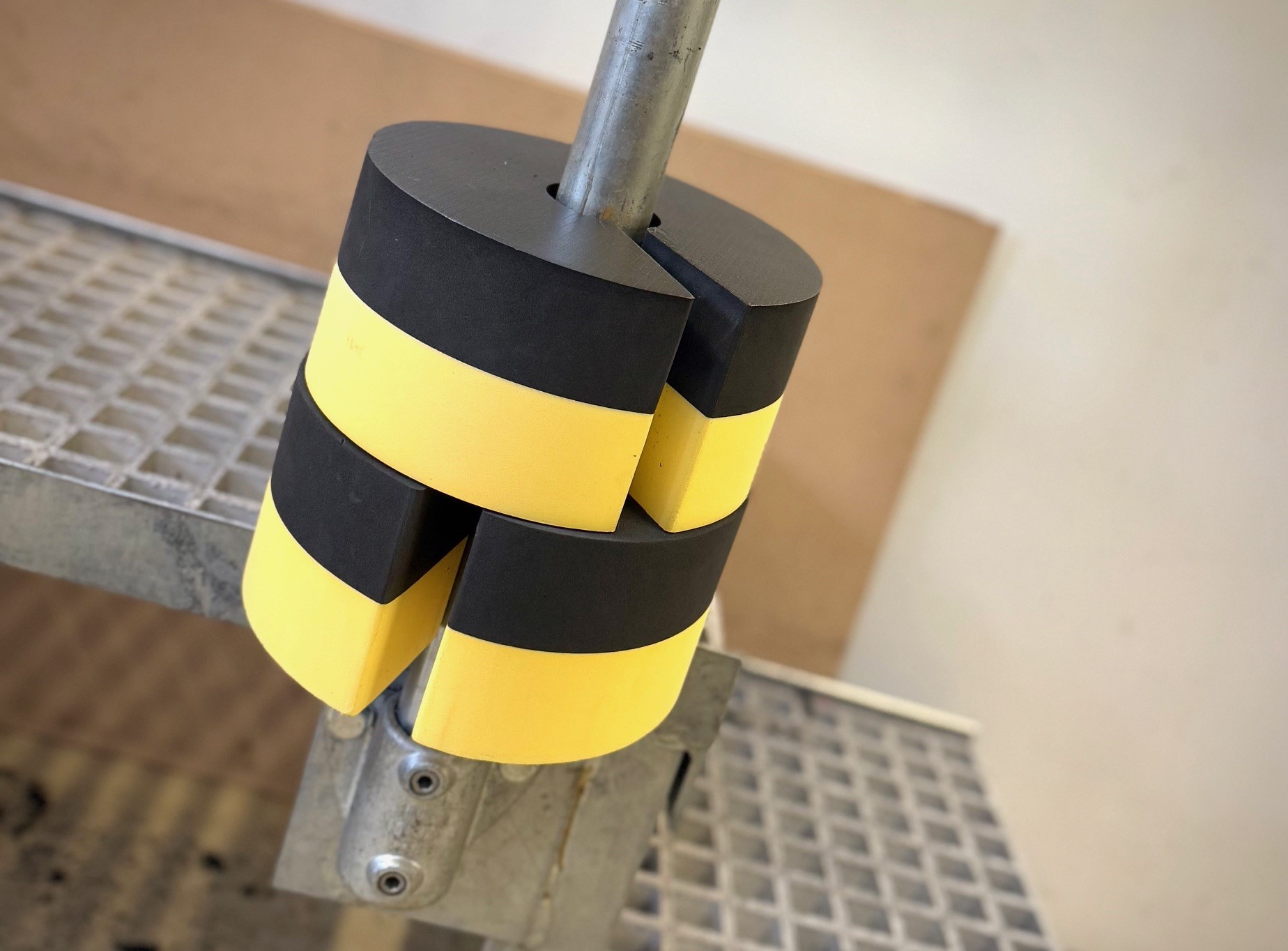

Impact Protection

Cases, Crates & Containers

Gaskets & Seals

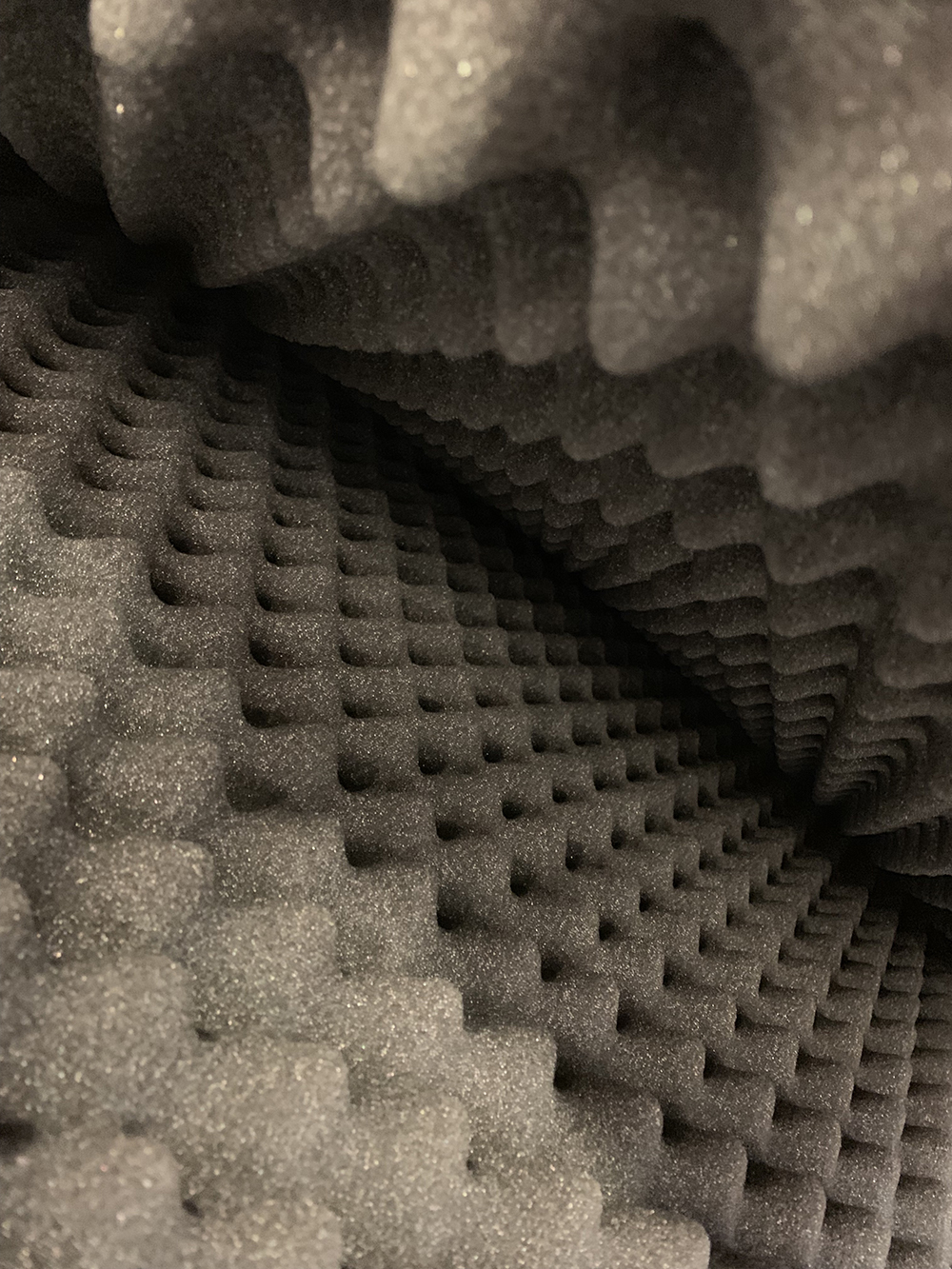

Thermal & Acoustic Insulation

High Temperature Foam Applications

Anti-Static & Conductive Foam

Expansion Joints

Construction Insulation

Buoyancy & Floatation

Filtration

Medical and Hygiene Foam

Foam Sponges and Specialised Sponge

EV battery foam

Museum & Conservation Foam Packaging

A reliable, streamlined supply partner

We’re more than a foam converter—we’re an extension of your engineering team. By managing supplier relationships and overseeing the full development cycle, we free up your internal resources and deliver faster, better results with fewer touchpoints. Our growing role in supply chain integration means we don’t just supply a part—we help you deliver a complete engineered solution.

Our vast stockholding of raw foam materials on-site—means we can respond quickly to urgent requirements without compromising quality or consistency.

Quality assured. Always.

Every batch of foam parts we produce are subject to strict quality assurance protocols. Whether your application requires flame retardancy, cleanroom compliance, or tight mechanical tolerances, we have the expertise and testing capabilities to guarantee performance and repeatability. All backed up with FAIR’s or CofC to your requirments.

We work to ISO9001 standards and align our QA processes with the expectations of highly regulated sectors such as defence, aerospace, and medical.

Foam that works as hard as you do

Not all foam is created equal. We work with the most trusted, proven, high-quality foam materials on the market—materials that are specifically chosen to perform in extreme conditions, from battlefield deployments to aerospace cabin interiors. Our engineers know how to get the most from each foam type—its tolerances, limitations, and capabilities—so we can deliver maximum functionality, with minimum waste.

Custom foam inserts

Protective packaging for sensitive equipment

Seals, gaskets and foam spacers

Structural and insulative panels

Thermoformed and CNC-routed foam parts

Talk to us early, get the best result

Our clients range from Tier 1 defence suppliers to aerospace OEMs to advanced industrial manufacturers. We’d love to learn more about your challenges and show you how our bespoke foam capabilities can help.

Let’s create something engineered and magical, not just ordered.

Get in touch with the Kewell Converters team today to discuss your next project.