EV battery foam

Bespoke, high-performance foam parts and solutions for the fast-growing EV battery sector

As electric vehicle (EV) innovation accelerates, so do the demands placed on components inside every battery pack. At Kewell Converters, we specialise in manufacturing bespoke foam solutions that meet the rigorous demands of EV battery applications including protection, insulation, sealing and structural integrity. With over 50 years of experience as one of the UK’s last remaining independent foam converters, we help OEMs and Tier 1 suppliers reduce risk, streamline production, and optimise performance.

Custom foam parts for critical EV battery applications

In the electric vehicle sector, managing heat, vibration, and space within battery packs is essential. Our high-quality foam materials, engineered in partnership with trusted brands like Zotefoams, provide durable, lightweight, and compliant solutions.

As a UK supplier of foam for EV batteries, we understand the exacting standards required by automotive manufacturers and engineers. That’s why every foam part we produce is precisely fabricated using our in-house CAD design, advanced machinery, and specialist engineering expertise.

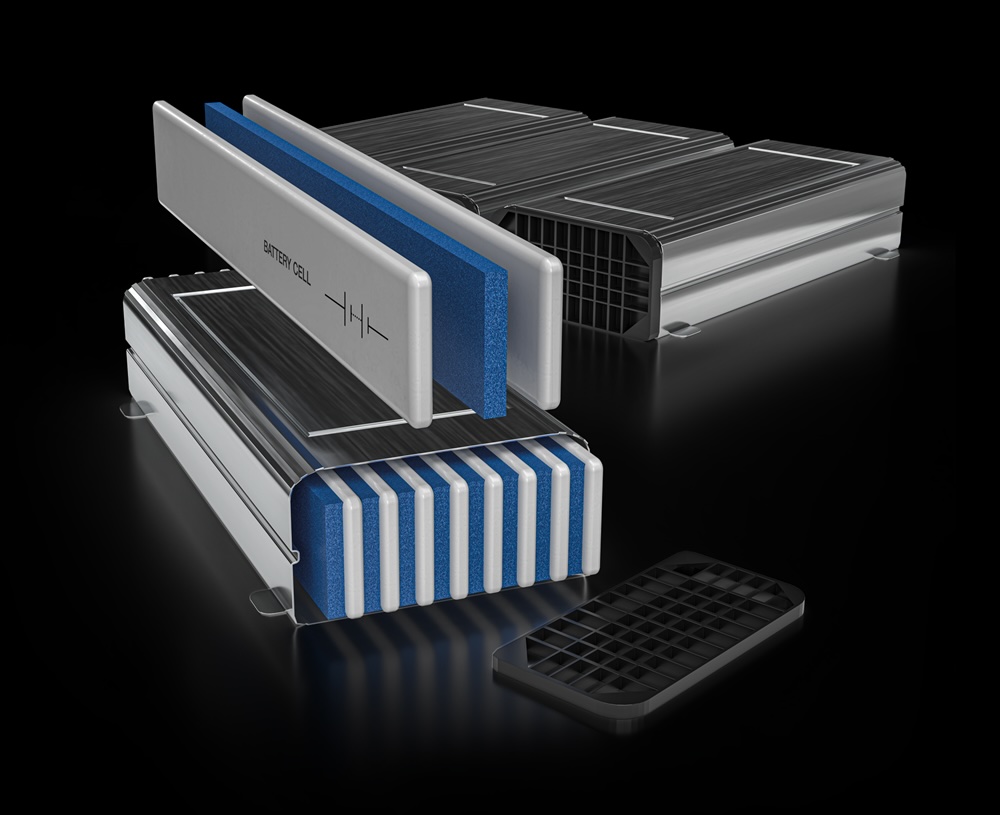

Compression pads and cell dividers

Absorbing impact and allowing cells to expand and contract without damage

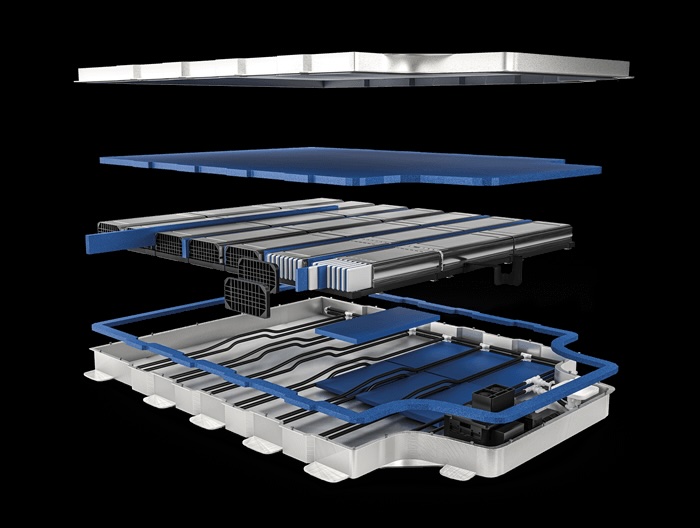

Thermal insulation and flame protection

Helping maintain battery temperature and prevent thermal runaway

Seals and gaskets

Protecting against dust, debris and water ingress to meet IP-rated sealing requirements

Cushioning and impact protection

Defending sensitive cells from shocks during assembly or real-world use

Why work with Kewell Converters for EV battery foam solutions?

50 years of exclusive foam expertise

Unlike many other suppliers who work with rubber or other materials too, we’ve focused solely on foam for five decades. That means we know how to get the best out of every foam type, whether it’s polypropylene, silicone, PE, PU, or the latest fire-retardant specialty foams.

Problem-solvers, not just part makers

We don’t just cut foam. We solve challenges. Our team works with clients from concept through to production, advising on material choice, performance targets, and design optimisation, reducing time, waste, and cost.

Seamless project management

We increasingly manage full projects, including sourcing, prototyping, fabrication, and supplier coordination, so our customers don’t have to. That means fewer handovers, lower admin costs, and faster turnaround from brief to part.

Trusted with the most demanding sectors

We’ve created custom foam solutions for sectors like aerospace, defence and motorsport, industries where performance, compliance and consistency are non-negotiable. That same dedication is applied to every EV battery foam application we handle.

Zotefoams & advanced materials for EV batteries

We work closely with Zotefoams to deliver EV battery-compliant foam solutions that meet the latest industry demands.

Our engineers will help you select the most suitable branded foams based on your project’s thermal, mechanical and compliance needs.

AZOTE® LDPE foams

Lightweight, thermoformable, fire-retardant options for cushioning and insulation

ZOTEK® F and T ranges

Flame-retardant, chemically resistant, high-temperature foams for structural and thermal management

New PP foams

Flat compression response, recyclable, and consistent performance over charge/discharge cycles

Typical foam applications in EV battery packs

We manufacture custom foam parts for:

- Thermal insulation layers

- Cell spacers and compression pads

- Protective foam inserts

- Gaskets and sealing profiles

- Foam panels and strips

- Flame barrier components

- Gap fillers and cushioning supports

All parts are cut or formed with precision to meet your design tolerances and ensure exact performance.

Your partner in EV battery innovation

Whether you’re a procurement manager looking for a reliable UK foam fabricator, or an engineer developing a next-gen battery pack, Kewell Converters delivers the specialised foam solutions and technical support you need.

Let us help you:

- Reduce part failure and warranty claims

- Ensure thermal, structural and sealing performance

- Simplify your supplier network

- Meet compliance and safety targets

- Increase value without increasing costs

Looking for a trusted foam converter for your EV project?

Get in touch today to discuss your EV battery foam requirements with our expert team. Whether you need advice, a quote or a prototype – we’re here to help.

Contact Kewell Converters for a fast, expert response.

FAQs

We use a wide range of materials including PE, PP, PU, silicone, PVDF and encapsulated aerogels – depending on thermal, structural, and safety needs. Most parts use Zotefoams’ AZOTE® or ZOTEK® ranges.

Foam materials are essential for thermal insulation, flame retardancy, and impact protection. They help prevent thermal runaway, cushion battery cells from vibration, and maintain safe operating temperatures, making them critical to overall battery safety.

Yes. We produce compression pads and spacers using materials like polypropylene (PP) foam and silicone foam, which allow for dimensional changes during charge/discharge cycles. This helps extend battery life and prevent cell damage.

Absolutely. We work with high-performance foam materials like ZOTEK® F, ZOTEK® T, and flame-resistant PVDF foams, which can handle wide temperature ranges and comply with automotive fire safety standards.

Yes. Many of the foam solutions we use, including Zotefoams’ branded foams, are certified to UL 94 V-0 and FMVSS 302, making them suitable for EV battery packs where fire performance is essential.

Definitely. Our engineering team works closely with customers to understand mechanical, thermal, and chemical performance needs, then recommends the best foam material and design based on the application and compliance requirements.

Yes. We manufacture custom gaskets, seals, and sealing profiles that prevent water ingress and environmental contamination. These are vital for meeting IP ratings and protecting EV battery systems in all conditions including wading tests.

We’ve supported leading automotive, defence and aerospace clients to develop bespoke foam parts for their battery packs and systems.

Yes. We offer non-crosslinked polypropylene foams (PP foams) that are recyclable, lightweight and cost-effective, making them a good choice for sustainability-conscious EV manufacturers.

Yes. Our team offers full CAD support from concept through to production. We help optimise designs for manufacturability and material efficiency.

We focus on bespoke foam solutions, from small-batch prototypes to high-volume production. Let’s talk about your specific requirements.