Automotive & transport

Bespoke foam components for safety, efficiency, and reliability

For over 50 years, Kewell Converters has specialised exclusively in foam conversion and fabrication, creating engineered foam solutions for some of the most demanding sectors worldwide. In automotive and wider transport applications, our bespoke foam parts deliver measurable benefits: reducing weight, improving fuel efficiency, enhancing passenger comfort, and ensuring compliance with strict safety standards.

By combining advanced materials such as Plastazote®, Evazote®, Ecozote®, Supazote®, and ZOTEK® N, with in-house CAD design and cutting-edge manufacturing techniques, we help procurement, quality, and production teams streamline supply chains while achieving long-term performance gains.

Automotive foam applications

Lightweight, durable, and compliant solutions for modern vehicles

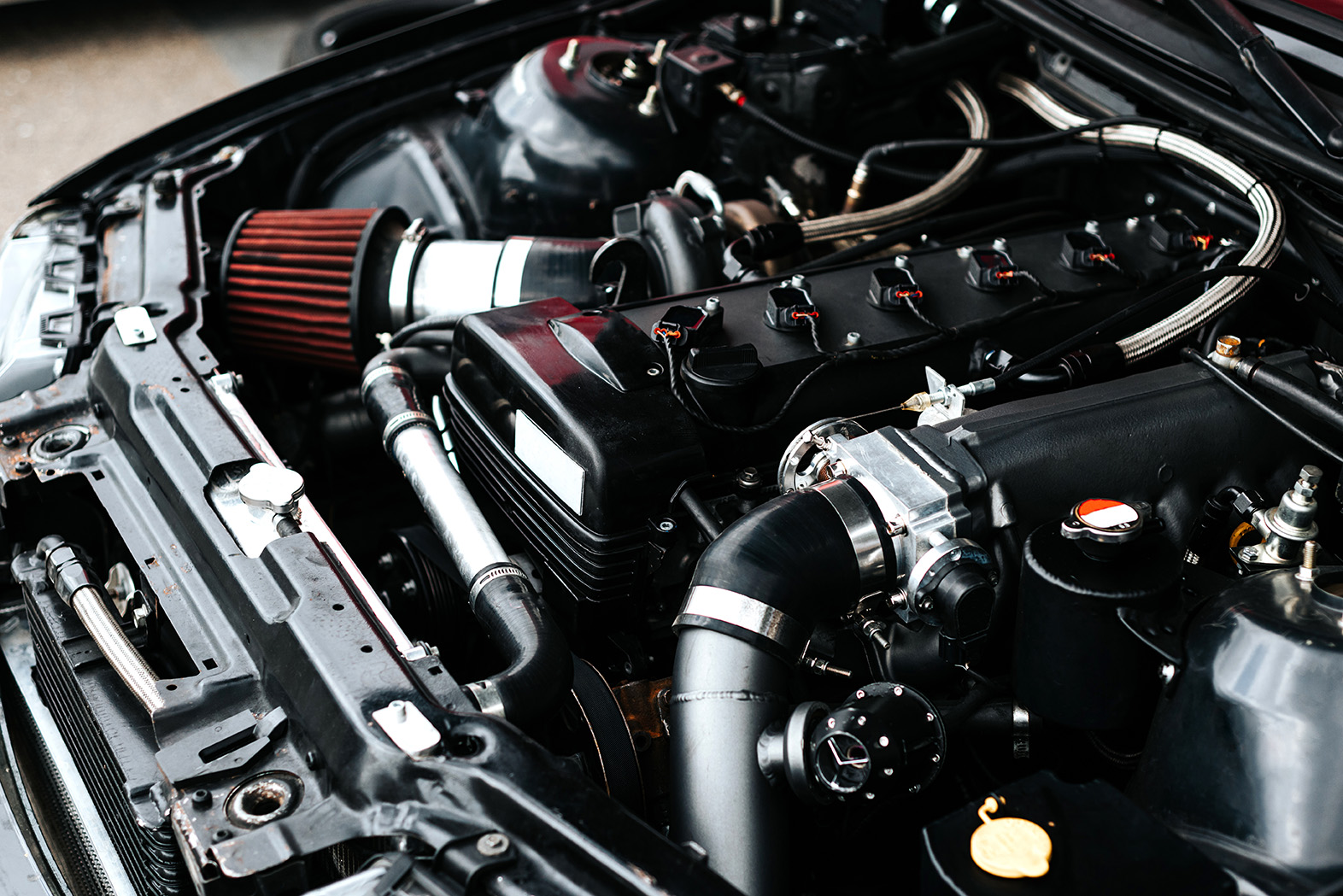

In the automotive industry, weight reduction, durability, and emissions compliance are critical. Kewell Converters develops custom foam parts that integrate seamlessly into vehicles, improving efficiency without compromising safety.

Typical applications include:

- Gaskets & seals – closed-cell foams resist water, oils, coolants, and greases, making them ideal for door seals, HVAC systems, and under-bonnet components

- Thermal & acoustic insulation – lightweight foams cut heat transfer and road noise, improving passenger comfort while meeting NVH and emissions targets

- Engine compartment parts – ZOTEK® N polyamide foams offer exceptional high-temperature resistance and compatibility with hydrocarbons, ensuring reliability under extreme conditions

- Interior components – low-VOC, low-odour foams minimise fogging and deliver a better cabin environment by eliminating “new car smell”

- Protective inserts – custom-cut packaging foam and Euro box inserts protect sensitive automotive parts during storage and transit

Our foams meet international compliance standards including FMVSS 302 flammability, VDA 277/278 VOC analysis, and DIN 75201 fogging resistance, giving manufacturers full confidence in safety and regulatory performance.

Why work with Kewell Converters?

- Unrivalled expertise – 50 years working exclusively with foam

- Independent and specialist – access to leading branded foams including Zotefoams’ AZOTE®, and ZOTEK® range, plus Palziv’s Palfoam and Galfoam, plus many others.

- Engineering-led process – full CAD design, prototyping, and advanced foam fabrication (CNC routing, water jet cutting, thermoforming)

- Supply chain efficiency – we manage sourcing, conversion, and quality, reducing supplier complexity

- Trusted by high-reliability industries – military, defence, aerospace, rail, and automotive leaders rely on our solutions

Start your project with us

Whether you need automotive-grade gaskets, lightweight insulation foams, or bespoke protective inserts, Kewell Converters has the expertise to deliver precision foam solutions that add value across your projects.

Get in touch with our team today to discuss your automotive and transport requirements.

FAQs

Closed-cell AZOTE® foams provide excellent resistance to water, oils, and coolants, making them ideal for long-lasting seals.

Yes. ZOTEK® N foams are specifically designed for engine compartments and aerospace applications, offering reliable high-temperature and chemical resistance.

Our lightweight engineered foams replace heavier materials, improving efficiency and reducing CO₂ emissions.

Absolutely. Our foams are tested for flammability (FMVSS 302), VOC emissions (VDA 277/278), and fogging resistance (DIN 75201).

Yes. We produce precision-cut inserts for Euro boxes, tool cases, and protective packaging to safeguard sensitive components.