Industrial Engineering

Precision-engineered foam solutions for demanding applications

For more than 50 years, Kewell Converters has specialised exclusively in foam conversion, helping some of the world’s most demanding industries, including defence, aerospace, and advanced manufacturing, solve complex engineering challenges. Our bespoke foam solutions are trusted where precision, durability, and compliance can’t be compromised.

Kewell Converters is an independent UK-based foam fabricator with unrivalled expertise in specialist foams. We combine in-depth material knowledge with full CAD design, CNC machining, and advanced fabrication processes to deliver engineered foam parts that perform consistently, even in extreme environments.

Why procurement and supply chain teams choose Kewell Converters

We understand that your role is not just to source parts, but to secure dependable supply chains, reduce risk, and ensure compliance. That’s why Kewell Converters offers more than just foam products. We act as a partner, managing the design, sourcing, and manufacturing process on your behalf.

This means fewer suppliers for you to manage, faster lead times, and absolute confidence that your foam components will arrive on time, on spec, and ready for integration.

Engineered foam products we supply

Our manufacturing capabilities extend far beyond simple sheet conversion. We produce:

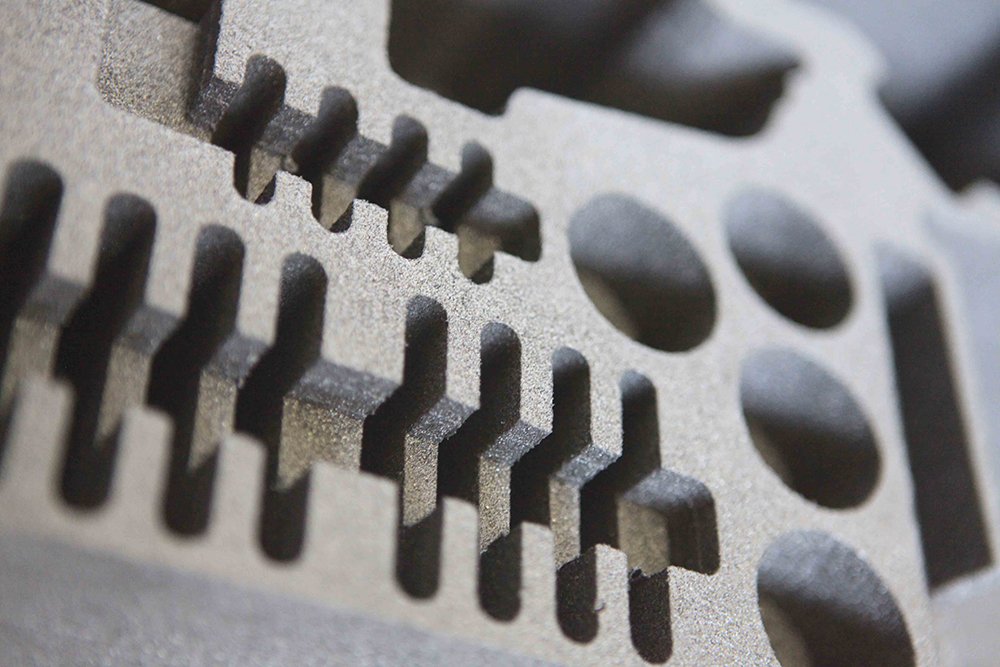

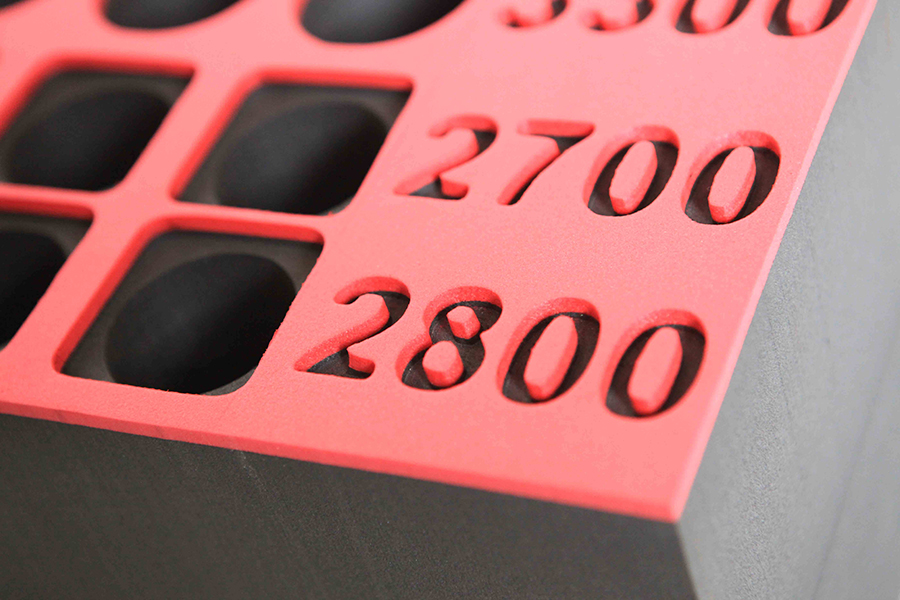

- Foam inserts for Euro containers and Euro boxes – custom-cut for secure handling and transport

- Protective foam packaging & case inserts – including flight case foam, plastic case foam (offer brands such as Peli, RoseCase, Storm and Nanuk), and tool box inserts

- Gaskets, seals, and foam strips – precision cut from EPDM, neoprene, and polyethylene foam

- Thermal and chemical-resistant foams – high-performance materials for aerospace, defence, and industrial applications

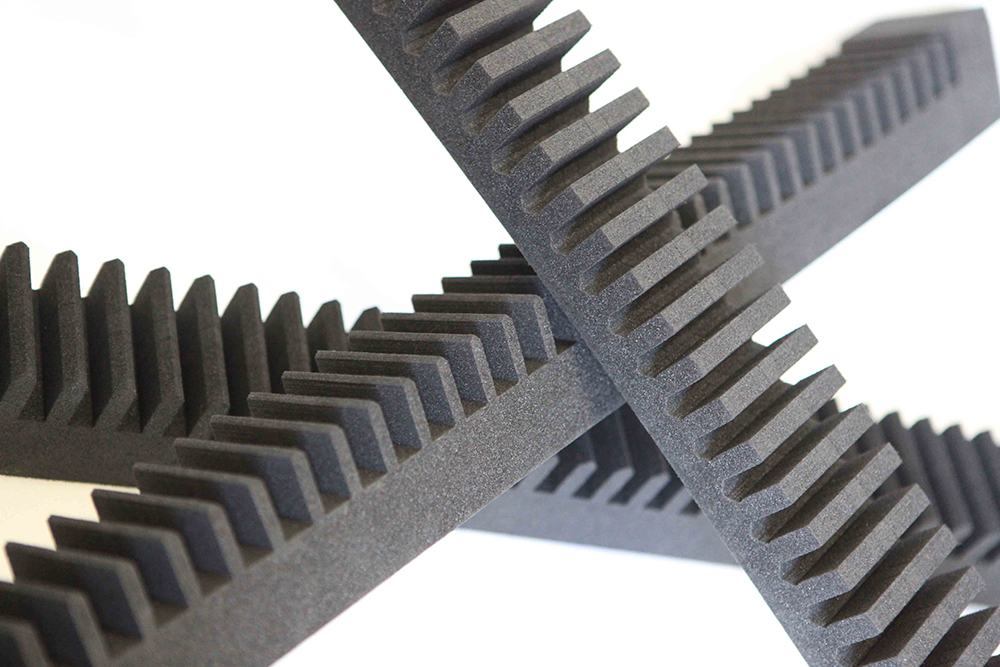

- Lightweight engineered foam panels & shapes – CNC routed or water-jet cut for accuracy and repeatability

- Conductive and static-dissipative foams – protecting sensitive electronics and avionics

Our expertise covers the full spectrum of foam materials, including Plastazote®, Evazote®, Supazote®, Zotek ®, Ecozote®, Ethafoam®, polyethylene, EVA, polyurethane, reticulated, neoprene, and high-density specialty foams.

Ready to discuss your project?

Whether you need Euro container inserts, high-temperature foams, or a fully bespoke engineered solution, Kewell Converters can help.

Contact our team today to start your next project.

FAQs

Yes. More of our customers now rely on Kewell Converters to manage sourcing, design, prototyping, and production. We liaise directly with approved suppliers and manage the process end-to-end, reducing your supplier base and simplifying procurement.

Every project benefits from full CAD design input by our in-house engineering team. This ensures optimum performance, cost efficiency, and seamless integration with your wider project. We can also provide prototypes for validation before full-scale production.

Yes. We regularly supply MoD-approved foams and aviation-grade foams with full material traceability and compliance to stringent defence and aerospace standards. Many of our projects involve protective packaging, gaskets, and inserts for mission-critical equipment.

Lead times vary depending on complexity, but we always try to turn around urgent projects quickly without compromising on quality.