Filtration

High-performance filter foam tailored to your needs

At Kewell Converters, we specialise in the design, conversion, and fabrication of high-quality filter foam solutions tailored for demanding applications across the military, defence, aerospace, and wider industrial sectors.

When you’re sourcing advanced filter foam components, we help procurement professionals, quality managers and engineers streamline the specification and production process, reducing complexity, enhancing performance, and ensuring quality at every stage.

What is filter foam?

Filter foam is a lightweight, open-cell polyurethane foam designed to trap particulates from air or liquids while allowing effective flow. It’s highly versatile and can be engineered to suit different densities, porosities, and chemical resistances — making it ideal for HVAC systems, automotive components, industrial machinery, and cleanroom or medical filtration.

Filter foam offers:

- Excellent airflow with fine particulate capture

- Durability and flexibility under extreme conditions

- Customisable formats, from sheets and panels to complex 3D foam parts

- Moisture and chemical resistance (depending on foam type)

Why leading sectors trust Kewell Converters for filter foam

We understand that no two projects are the same. Our in-house team of specialist foam engineers and CAD designers will work with you from concept through to production — ensuring that every foam part we supply performs exactly as needed, in the environments it’s designed for.

We add value through design, conversion, and integration.

We provide:

- Bespoke filter foam solutions engineered to spec

- Full CAD support for design optimisation

- On-site CNC machining and in-house testing

- Experience with flame-retardant, chemically resistant and temperature-tolerant foams

- Seamless supply chain management – from sourcing to final part delivery – we deliver a smarter, simplified process that reduces procurement workload and risk

Applications of filter foam

HVAC systems

Our air filter foam is essential in commercial and industrial HVAC systems, helping maintain air quality by trapping pollen, dust, mould spores and other contaminants. High-efficiency foam materials contribute to reduced energy use, improved indoor health, and longer system lifespans.

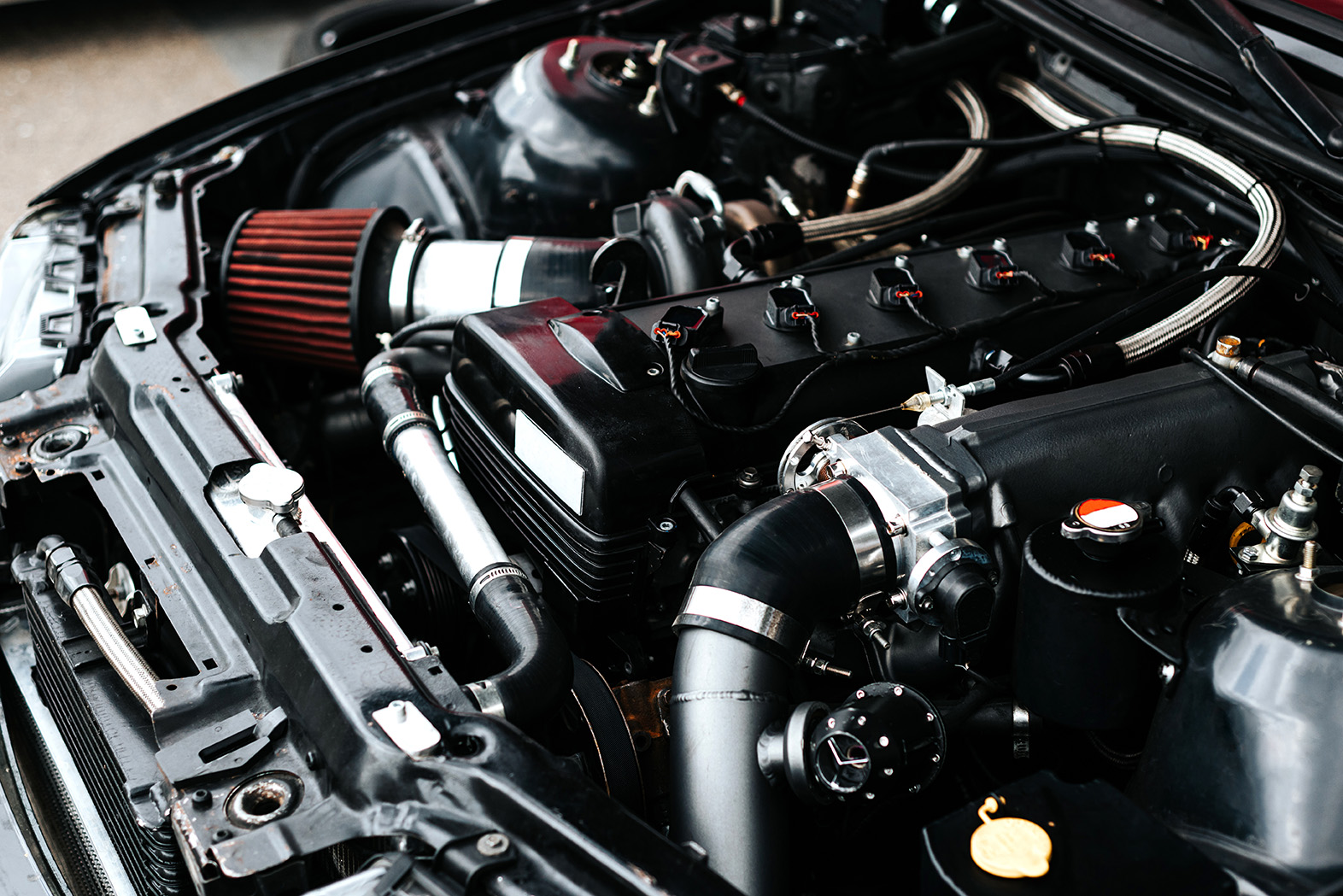

Automotive components

Filter foam is a frontline defence for engine health. It stops debris from reaching sensitive engine parts, improving fuel efficiency and minimising wear. Our clients benefit from highly resilient foams that perform under pressure and heat, ensuring reliability and compliance.

Industrial & medical filtration

From fluid filtration in manufacturing equipment to air handling in cleanrooms, we supply custom filter foam parts tailored to the chemical, mechanical and environmental demands of each system.

Ready to specify high-quality filter foam?

Let’s talk. Whether you need a rapid prototype, a batch of foam inserts, or a long-term engineered solution, our team is here to help. We work with clients who demand the highest performance from their materials — and we deliver every time.

FAQs

Filter foam is used to trap particles while allowing air or liquids to flow through. Common uses include air filter foam for HVAC systems, automotive air filtration, and industrial or medical filtration.

It depends on your application’s flow requirements and the size of the particles you need to trap. Our team will guide you through material selection to balance filtration performance with system efficiency.

Substandard foam can reduce flow, let particles through, and degrade quickly. Our custom foam parts improve system efficiency, reduce maintenance, and extend product lifespan.

We offer bespoke foam solutions backed by 50 years of experience, advanced CAD design, in-house production, and end-to-end project support — all from one UK-based foam converter.