6th February 2026

What defence and aviation buyers should know about foam compatibility and compliance

Read more >

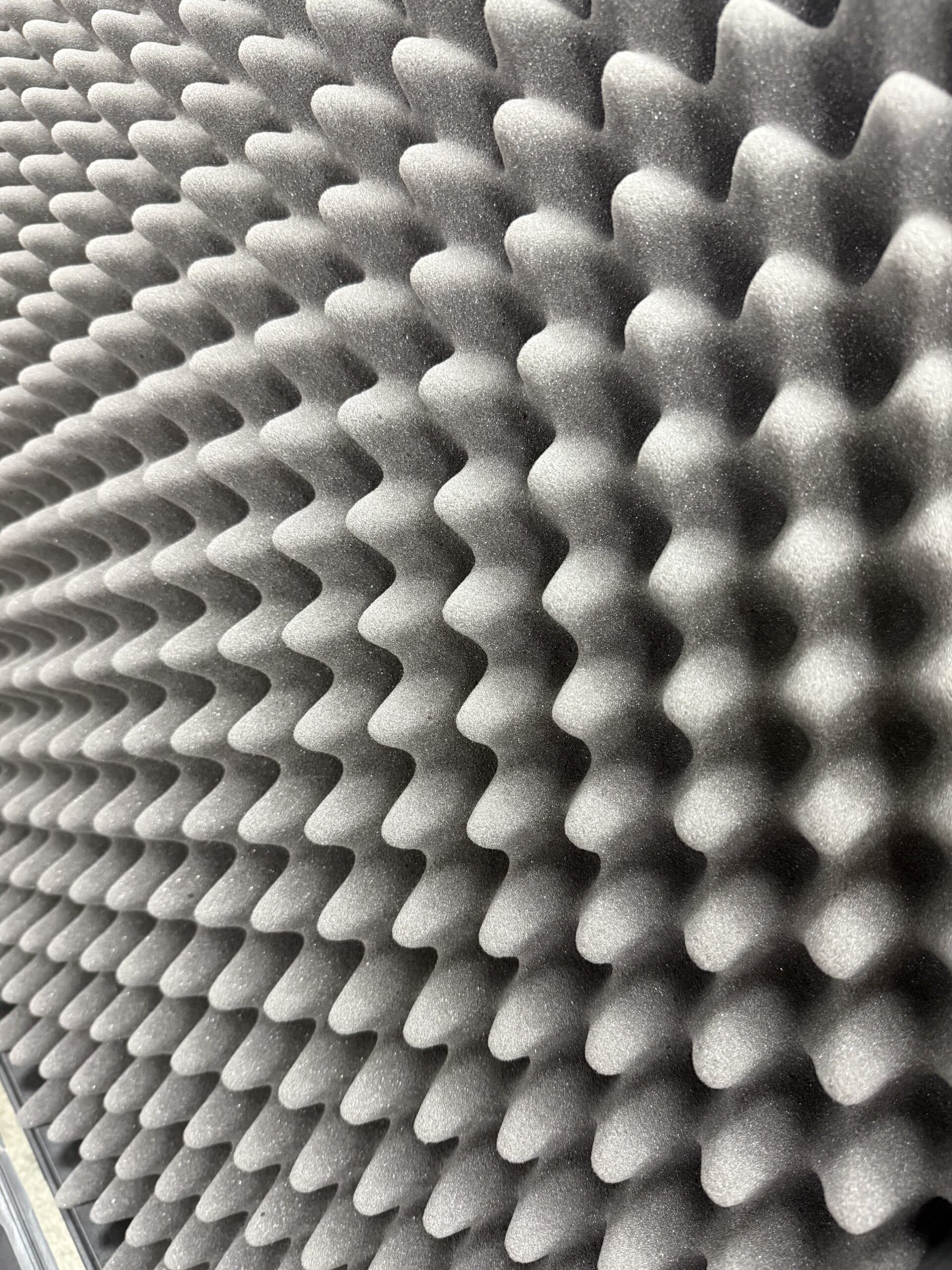

Foam has always played an important role in engineering, although it is often one of the least visible materials in any project. Over the past few years, interest in engineered foam has grown steadily as more industries look for materials that can offer precision, consistency and specific performance characteristics. What we’ve seen during 2025 isn’t a sudden shift in the market, but a clearer recognition of just how essential foam has become in solving modern engineering problems.

Market research supports this steady rise in demand. Global forecasts for foam converting services point to reliable year on year growth driven by applications in packaging, medical devices, EV systems, electronics, aerospace and defence. The broader foam market also shows consistent expansion as new technologies and manufacturing processes require customised materials with specific thermal, acoustic and mechanical properties.

At Kewell Converters, this aligns closely with what we’ve heard and seen when speaking to customers at trade shows and during on site visits. The conversations are evolving. Customers who once asked about general protection or cushioning now want to understand performance under pressure, behaviour at different temperatures, the need for long term consistency and how foam integrates into larger engineered systems.

Although the market itself hasn’t changed dramatically this year, customer expectations have continued to rise. More projects now require foams that can meet tight tolerances and deliver repeatable performance. This is especially true in sectors such as EV battery systems, aerospace interiors, defence equipment, electronics and semiconductors.

What has stood out to us this year is the level of technical detail customers expect. Engineers are asking about traceability, data, long term stability and how foam interacts with other materials inside a controlled system. We’ve witnessed how foam isn’t seen as just a commodity but as a functional component that directly affects reliability and safety.

This has quietly reshaped how many products are specified. It’s also created new opportunities for converters who can provide engineering led collaboration from concept through to production.

The converters who will thrive are those who can combine flexible manufacturing with strong technical understanding. The projects coming to us require material expertise, precision machining, rapid prototyping and support during early stage design. It’s no longer

enough to simply cut foam to shape. Customers want help interpreting specifications, exploring options and ensuring that the final parts will behave predictably in real conditions.

We’ve seen projects where foam plays a role in:

· Thermal management for electronics

· Fire resistance and safety-critical requirements

· Dampening and vibration control

· EV battery sealing and protection

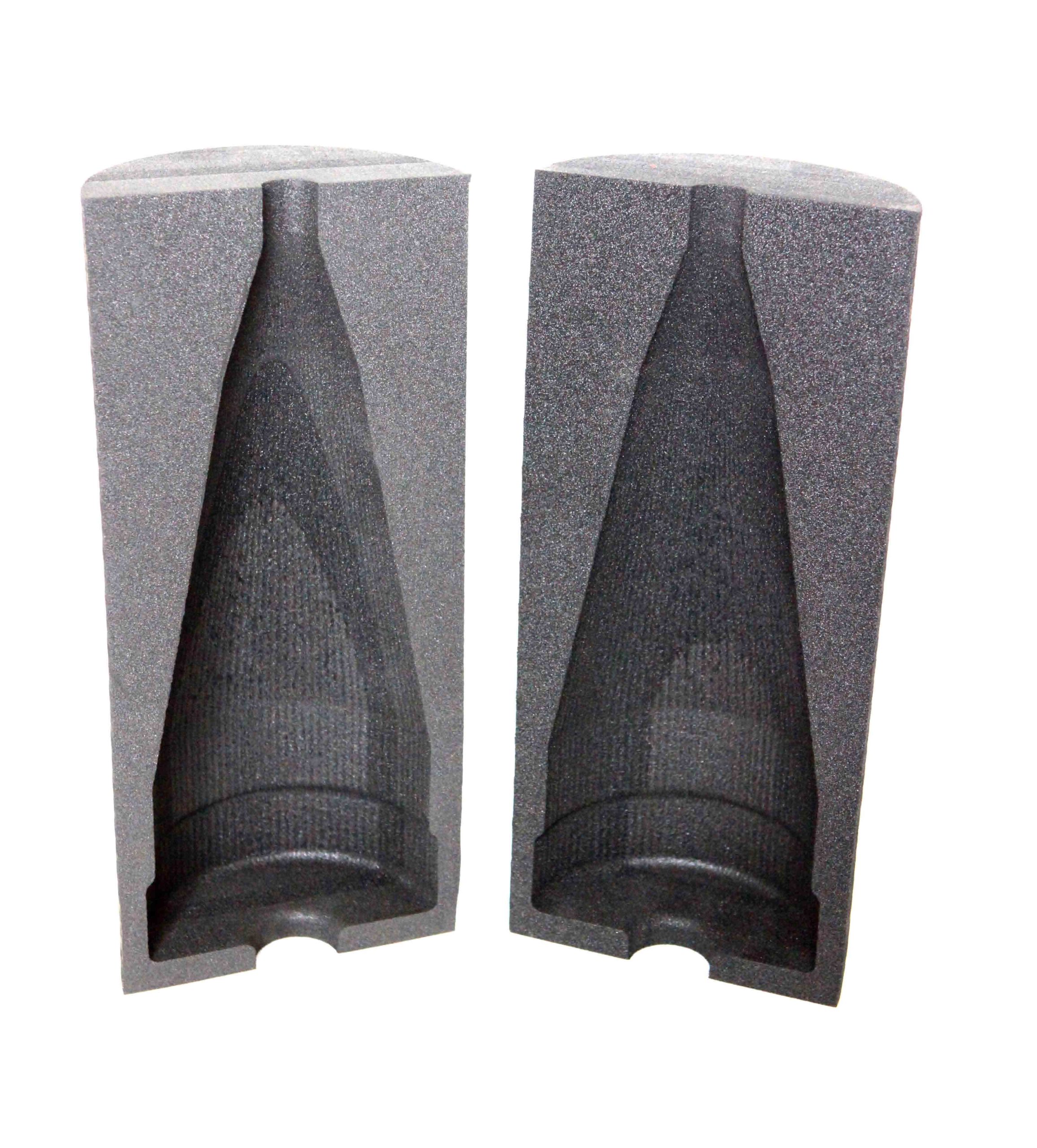

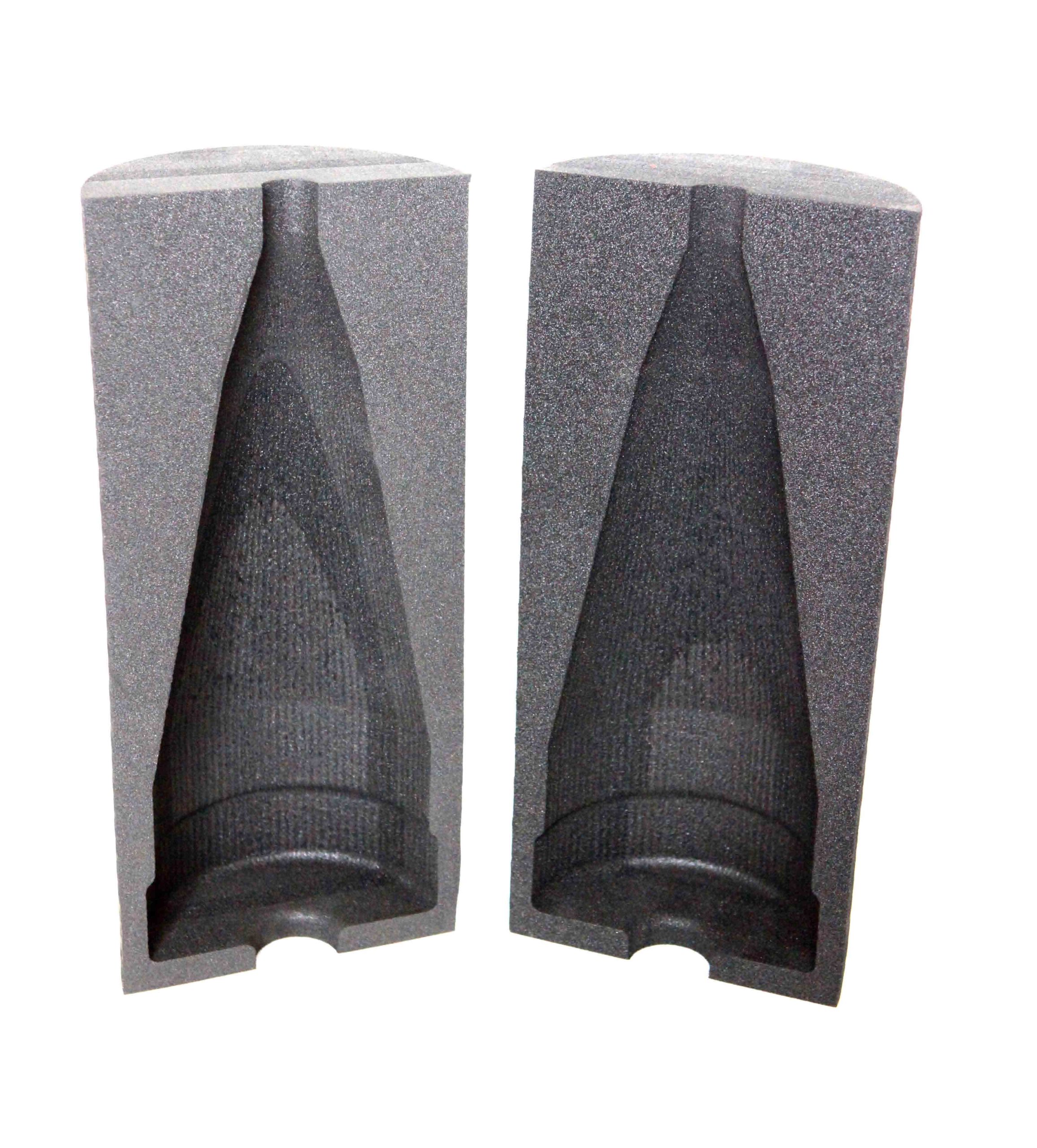

· Clean room packaging for sensitive components · Aerospace and defence grade assemblies

This steady broadening of applications shows that engineered foam is becoming more important, not less. It also highlights why close collaboration between converter and customer is essential.

Market forecasts suggest the foam conversion and engineered foam sectors will continue to grow at a reliable pace in the years ahead (Wise Guy Reports). As industries invest in electrification, automation and lightweighting, the need for custom foam solutions will increase.

We expect growth in several key areas.

Early stage involvement Foam will be considered at the design phase more often as engineers seek to optimise performance and reduce cost or weight.

Higher expectations around quality and traceability Customers increasingly require consistent performance across batches and detailed origin data for materials.

Thermal and fire performance As systems become more compact and energy dense, foams designed to manage heat and meet fire regulations will be in higher demand.

Sustainability and material innovation There is growing interest in recyclable foams, high performance bio based materials and more efficient manufacturing processes that reduce waste.

More specialised applications EV, aerospace, defence, medical devices and high tech manufacturing continue to drive requirements for engineered solutions that cannot be met with off the shelf products.

Kewell Converters has always focused on technical performance, collaboration and precision manufacturing. The conversations we’ve had throughout 2025 reinforce that these

capabilities matter more than ever. Our team will continue to invest in expertise, equipment and processes that help customers turn complex challenges into practical foam solutions.

What we’ve seen this year is not a dramatic market shift but a steady increase in expectations and a deeper appreciation for the role foam plays in critical systems. This is a positive trend for both manufacturers and end users because it leads to better products, higher reliability and more innovation.

If you’re exploring how foam or performance materials could support your future systems, we’re always open to exchanging ideas, discussing new trends and learning from real engineering challenges. Get in touch with our team, we’d be happy to support you from the earliest stage of development.

6th February 2026

Read more >

16th December 2025

Read more >

11th November 2025

Read more >