6th February 2026

What defence and aviation buyers should know about foam compatibility and compliance

Read more >

In defence and aviation, materials are not just components, they are part of the safety system. Foam used in aircraft, military vehicles, weapons storage, and protective transit must perform reliably under extreme conditions and meet strict regulatory standards.

Foam compatibility and compliance are not optional. They determine whether systems remain safe, certifiable, and operational.

This guide explains what engineers, buyers, and quality professionals need to know about choosing foam for defence and aerospace applications, with insight from long-term work in these sectors.

Foam compatibility means how a foam material behaves with its environment, surrounding materials, and operational stresses.

“Foam failure in defence or aerospace usually isn’t dramatic, it’s silent. It shows up as vibration damage, heat distortion, or chemical breakdown over time. That’s why compatibility has to be engineered, not assumed.” Nick Kewell, Managing Director, Kewell Converters

In defence and aviation, compatibility must be assessed across four key areas:

Explosive-compatible foam must:

This is critical in:

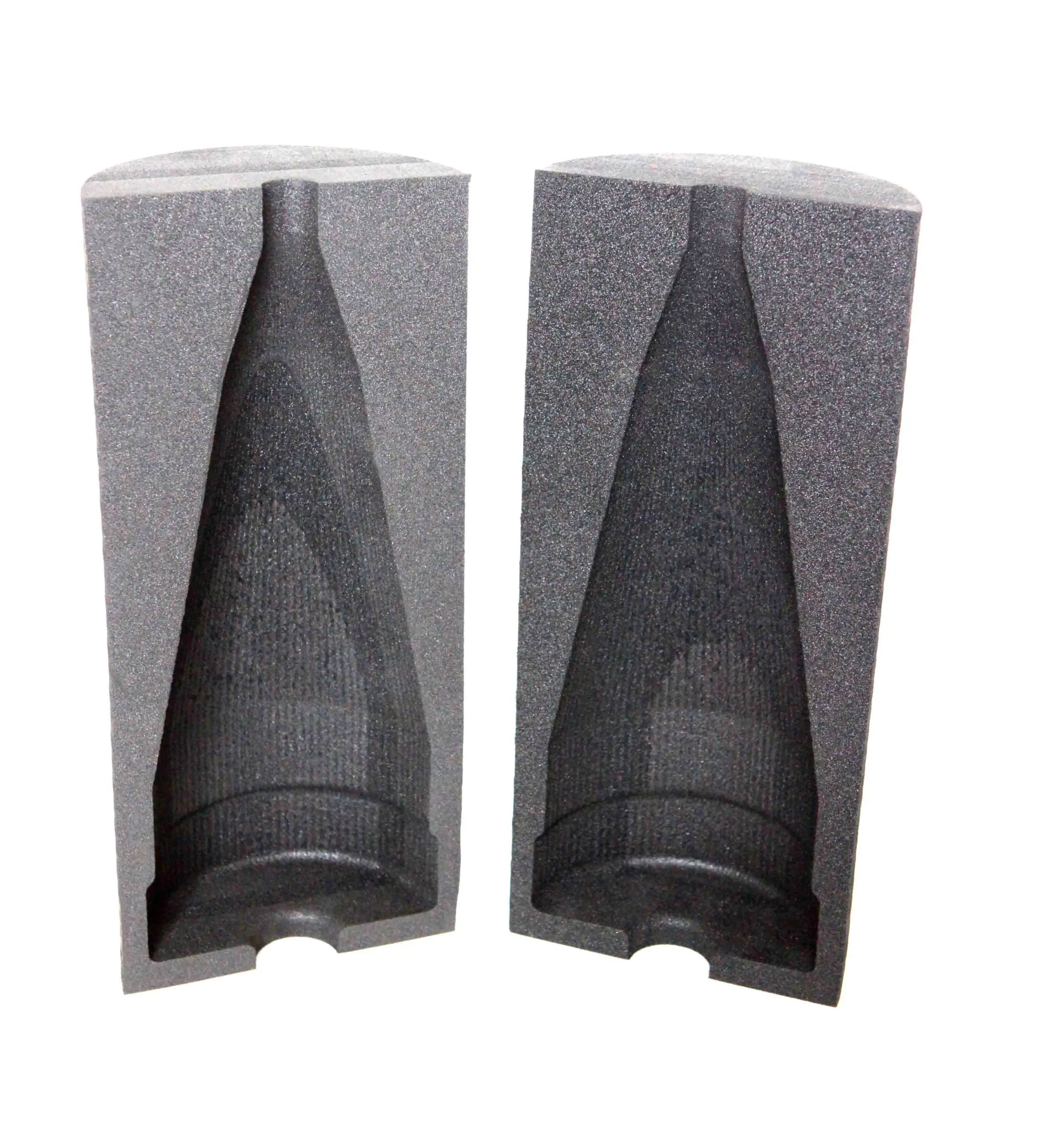

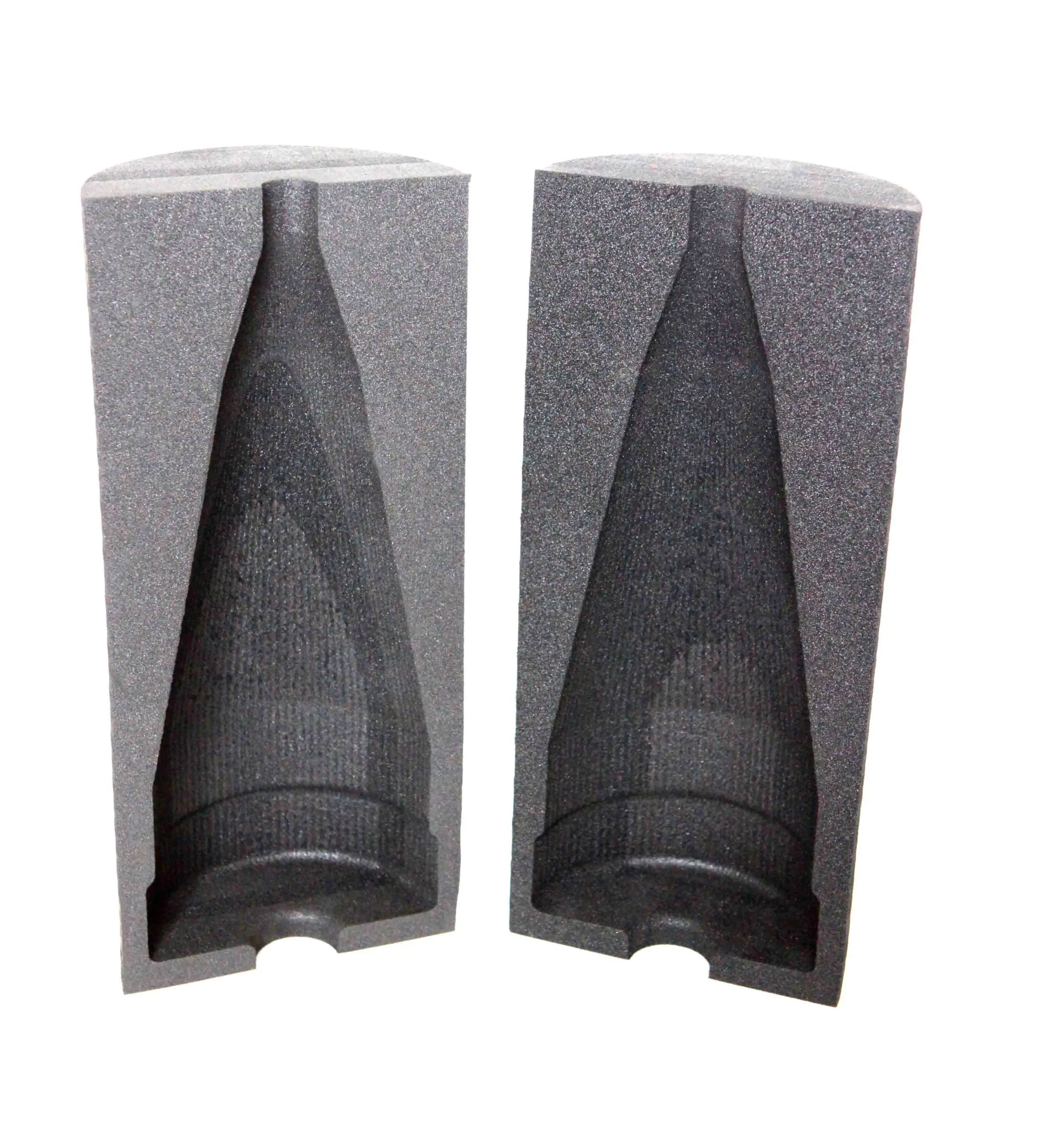

In practice, materials such as specialist grades of Plastazote and ZOTEK foams are often selected for these environments because of their stability, closed-cell structure, and predictable behaviour under stress.

Compliance means meeting formal standards for safety, traceability, and performance required by regulators, primes, and government bodies.

In defence and aviation, this typically includes:

Compliance is not just about materials. It also includes how components are designed, produced, inspected, and documented.

UL94 is a globally recognised flammability testing standard for plastics and foams.

It measures:

Many aircraft and interior systems require foams rated:

These foams are often used in:

In real projects, lightweight foams such as ZOTEK and flame-retardant grades of Plastazote are commonly used to balance fire performance, weight reduction, and mechanical strength.

In defence procurement, compliance usually includes:

Typical documentation includes:

Suppliers working with UK defence primes are often expected to be JOSCAR registered, demonstrating verified capability, compliance, and governance.

Choosing the wrong foam can lead to:

In defence and aerospace, compatibility and compliance failures are not just technical issues, they are operational and commercial risks.

“In regulated sectors, the wrong material doesn’t just fail in use. It fails in audit, certification, and programme timelines. That’s often more damaging than the physical failure itself.” Nick Kewell, Managing Director

In defence projects, incorrect material selection can lead to packaging that degrades in storage, inserts that fail vibration testing, and components that can’t be signed off due to missing traceability.

When specifying foam, buyers and engineers should ask:

Material choice should always be driven by application conditions, not just cost or availability.

A capable defence or aerospace foam supplier should provide:

Ideally, design, material sourcing, and conversion should be managed under one roof to reduce risk, miscommunication, and compliance gaps.

This approach has been proven in defence projects where packaging, vehicle interiors, and equipment protection all require tight tolerances, documented testing, and consistent quality across batches.

“Most issues we see could have been avoided with earlier material testing and clearer compatibility questions. Getting it right early always costs less than fixing it later.” Nick Kewell, Managing Director

If you are specifying foam for defence or aviation applications:

Foam may look simple, but in high-risk environments, it is a critical engineering decision.

If you are reviewing or developing a defence or aerospace foam application and want a second opinion on compatibility or compliance, speak to a specialist before locking in your material choice.

Nick Kewell is an engineer and the Managing Director of Kewell Converters, a UK-based foam conversion specialist with more than 50 years’ heritage in delivering engineered solutions for defence, aerospace and industrial applications.

Nick studied engineering and started his career on the technical side of manufacturing, giving him a deep understanding of materials, processes, and performance requirements. He brings this real-world engineering experience to every project, helping procurement teams, quality managers and design engineers make informed choices about foam compatibility and compliance especially where safety and certification are paramount.

Nick is part of the Kewell family legacy. He is the son of the company’s founder, the late Colin Kewell, and continues a tradition of engineering excellence rooted in innovation, precision and quality. Under Nick’s leadership, Kewell Converters has combined this heritage with modern engineering practices, advanced material knowledge and application-led design thinking, a journey he often reflects on in industry conversations and during engineering events like World Engineering Day. You can connect with Nick on LinkedIn.

6th February 2026

Read more >

16th December 2025

Read more >

11th November 2025

Read more >