Sustainable Foam

High-performance, eco-responsible foam for demanding applications

When sustainability matters as much as performance, Kewell Converters delivers. We’re proud to be a UK supplier of sustainable foam materials from trusted, responsible manufacturers such as Zotefoams and Apetek, chosen not only for their environmental credentials but also for their proven performance in mission-critical environments.

Whether you’re specifying foam inserts, gaskets, seals, or protective packaging, our sustainable foams offer you the strength, reliability and precision engineering you expect, without compromise.

Engineered for the toughest sectors. Now built for a greener future.

For over 50 years, Kewell Converters has specialised in bespoke foam fabrication for complex, high-value projects. Today, we continue to serve the aerospace, military, defence, and industrial sectors with sustainable foam solutions that meet both technical and environmental standards.

Every material we offer is selected based on its performance under pressure, from vibration resistance and thermal stability to durability in extreme operating conditions. Now, we apply the same scrutiny to sustainable foam materials, so you don’t have to compromise on quality to meet ESG goals or supplier mandates.

Our carefully selected range of high quality, sustainable foam materials

Ecozote® (from Zotefoams)

- Made with 30% recycled content

- Closed-cell, cross-linked LDPE foam

- ISO 14021:2016 certified

- Excellent for foam inserts, tool control, case linings, and lightweight protective foam packaging

- Performs to the same high standard as Plastazote®, with a significantly lower environmental impact

Ecozote PE/R

offers the same benefits as Ecozote®, with a fine cell structure and matt black finish ideal for premium/luxury applications.

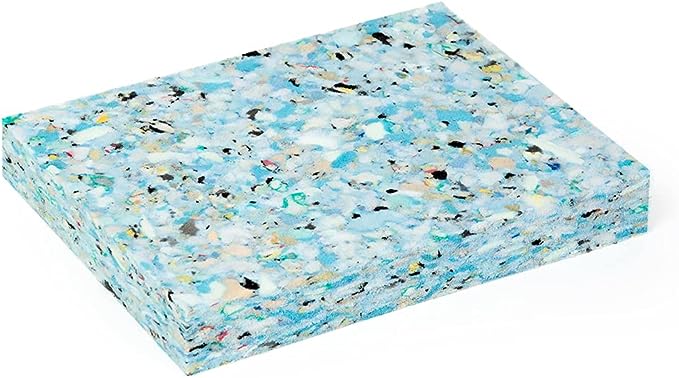

ApeteK Refo Protect P

- Produced using post-industrial XPE foam by-products

- Part of the Green Circular Economy

- Can be heat-welded to base foam materials for durable, block-based solutions

- Ideal for layered industrial applications where sustainability and structure are both required

Stratocell® R

- Contains minimum 65% recycled content

- Advanced cushioning for protective packaging

- Reduces overall material use

- Delivers performance similar to virgin foams, with lower cost and improved sustainability

Arplank®

- Closed-cell EPE bead foam

- 100% recyclable; up to 30% post-consumer recycled content

- Outstanding energy absorption and weight reduction—up to 40% less material vs traditional PE foams

- A top choice for protective foam packaging, military cases, or aerospace components needing both durability and weight savings

Why choose Kewell Converters?

We don’t just supply foam, we solve problems. Our in-house engineering team works with you from concept to final cut, optimising every part for performance, cost, and sustainability. You benefit from a single point of contact managing the sourcing, design, and manufacture, saving you time, reducing risk, and helping you meet procurement or regulatory requirements with confidence.

Whether you need bespoke foam shapes, protective inserts, or manufactured foam solutions, we’ll help you choose the right specialised foam and get the most from it.

Our sustainable foam solutions

Sustainable packaging solutions

High-quality, bespoke foam transit packaging for the safe transport, handling, and storage of valuable and sensitive components.

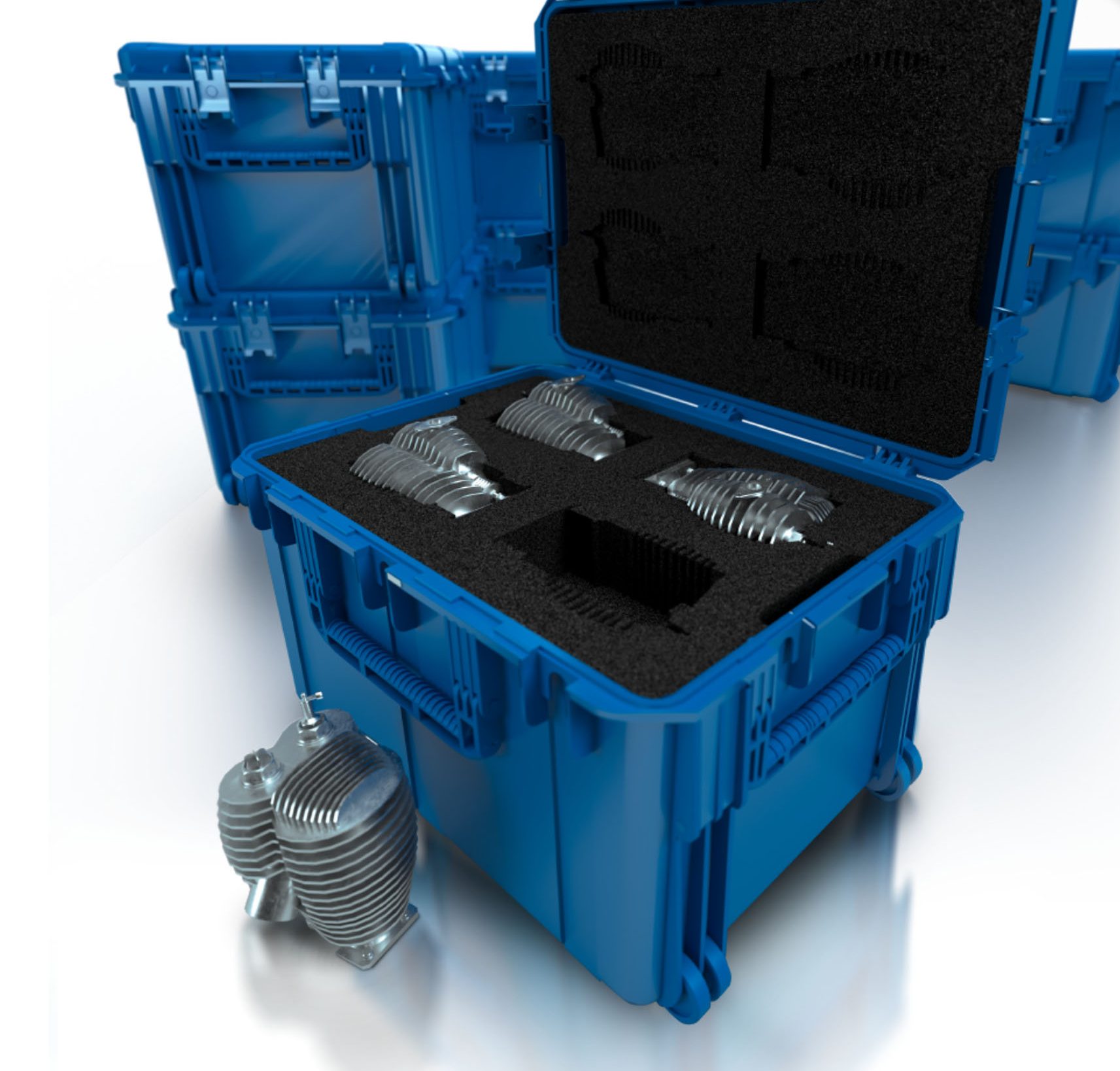

Sustainable flight cases and case inserts

Bespoke foam inserts and case systems designed to secure, transport and protect what matters most.

Bespoke sustainable foam solutions

Whatever you need, Kewell Converters can collaborate closely with you to create a custom foam solution that meets your ESG goals without compromising on quality.

Talk to our team about sustainable foams

Want help specifying a sustainable foam for your next project?

Get in touch with the Kewell Converters team today to discuss your requirements.

FAQs

Yes. All the sustainable foams we offer—such as Ecozote®, Stratocell® R and Arplank®—deliver performance on par with their non-recycled counterparts. They’re suitable for demanding applications including aerospace, defence, and industrial use.

Absolutely. Our experienced engineering team will work closely with you to recommend the best eco-responsible foam solution based on performance requirements, compliance, environmental goals, and budget. We’ll support you from material selection through to final part manufacture.

We hold stock of branded foams, including Zotefoams materials, enabling us to offer reliable lead times. For highly specialised or large-volume projects, we can also source materials as part of a managed supply chain process.

Yes. Many of the recycled-content foams we use meet the technical and regulatory standards expected in sectors like defence and aerospace. We regularly support projects requiring tight tolerances, consistent performance, and traceable sourcing.

We provide fully converted foam parts, custom foam inserts, gaskets, pads, and engineered shapes, all precision cut to your specification. We’re a foam converter, not just a material supplier, so you get complete, production-ready components.