6th February 2026

What defence and aviation buyers should know about foam compatibility and compliance

Read more >

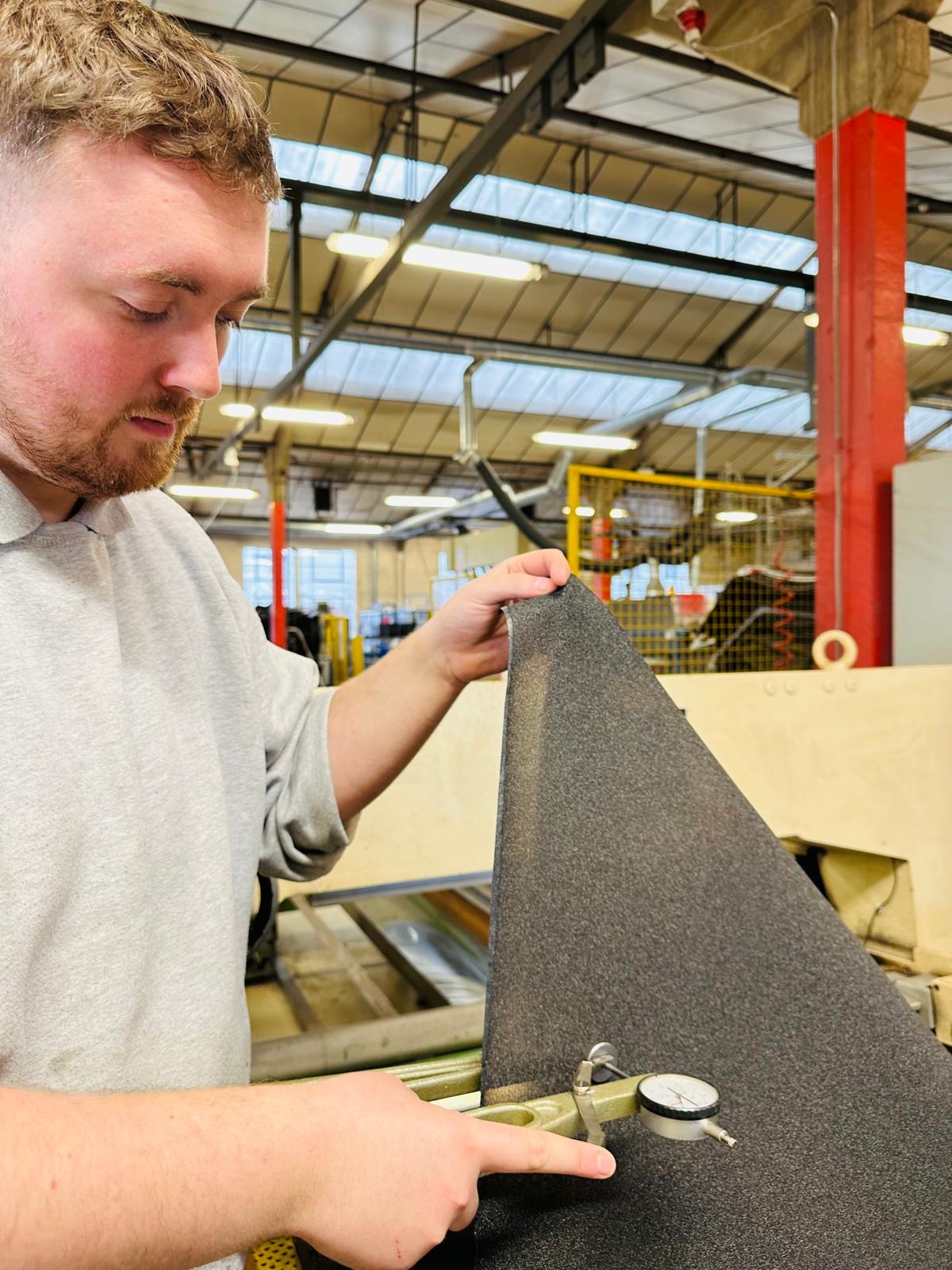

At Kewell Converters, we take great pride in nurturing talent and developing the next generation of foam engineers. Our team is full of dedicated individuals who are eager to innovate and refine the art of foam fabrication. Today, we focus on one of our rising stars: Jordan, a newly promoted production engineer who is blending traditional foam conversion techniques with fresh ideas.

Jordan’s journey to becoming a foam engineer is anything but conventional. Before joining Kewell Converters, he was training to be a chef. However, two years ago, he made a career shift and joined our prep team, where he quickly proved himself as a valuable asset. After a year of hands-on experience and learning the intricacies of foam parts and foam shapes, Jordan was recently promoted to production engineer—a role that perfectly suits his passion for precision and technical know-how.

As a production engineer, Jordan’s primary focus is increasing production efficiency. One of his proudest achievements so far is optimising cutting techniques to minimise material waste and reduce adjustments during the process. He discovered that standardising cuts to 6mm significantly reduces the need for fine-tuning, leading to fewer rejects and a smoother workflow. This kind of forward-thinking approach is exactly what makes a brilliant foam engineer—someone who listens to feedback, remains patient, and has strong time management skills.

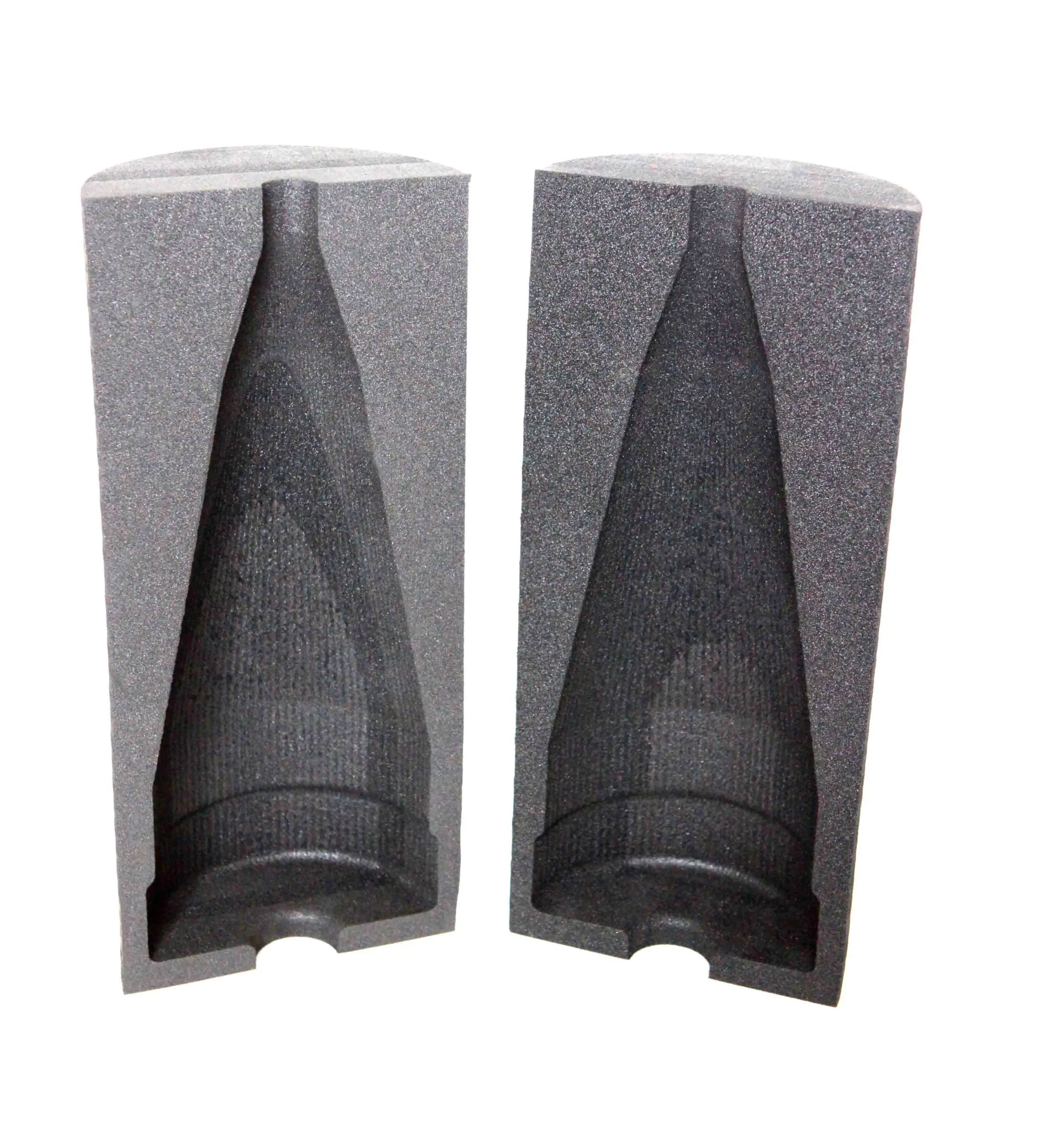

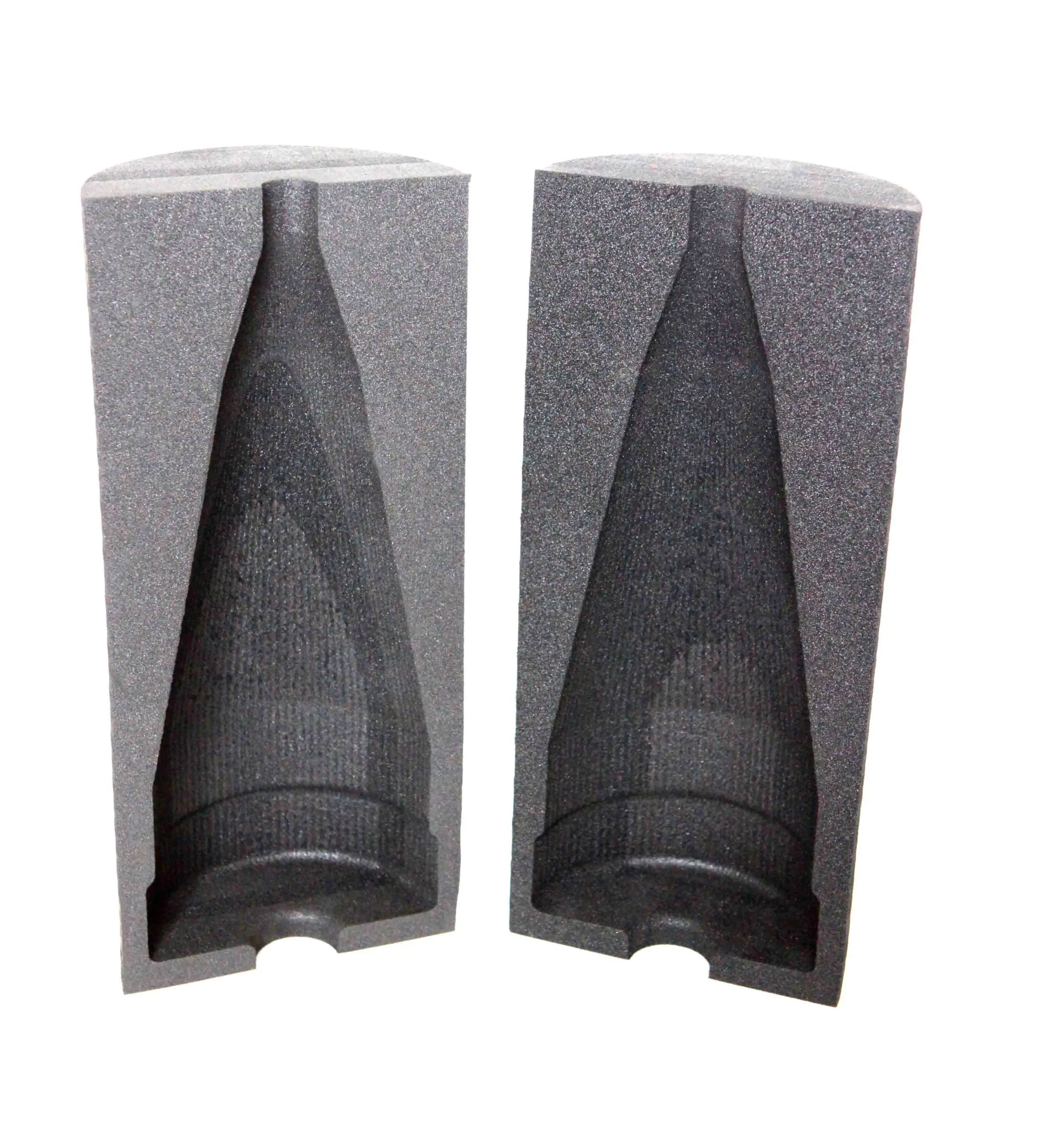

Jordan is also keen to expand his knowledge of our state-of-the-art machinery, particularly the contour cutters, which play a crucial role in precision foam fabrication. His enthusiasm for learning new techniques and refining old ones ensures that Kewell Converters continues to stay at the forefront of the foam conversion industry.

One of the things Jordan loves most about working at Kewell Converters is the team. He describes the work environment as social and family-like, which has made his transition from prep team to production engineer even more rewarding. Collaboration is at the heart of what we do, and Jordan embodies this spirit by constantly engaging with his colleagues to share insights and improve workflows.

His drive doesn’t stop at work—outside of the factory, Jordan is an avid golfer and football player. He enjoys a bit of healthy competition, whether on the field or when refining his skills as a foam engineer. And if you’re looking for an interesting fact about Jordan, here’s one: he owns a £300 limited edition bottle of Tabasco, which he won after baking an award-winning chocolate lava cake at North Kent College. Talk about a recipe for success!

One of Jordan’s latest projects involves reviving an old piece of equipment—the pad printer. This machine had been in storage, but with his keen interest in exploring new and old technologies, Jordan has taken the initiative to get it repaired. Once fully operational, the pad printer will add another dimension to our foam fabrication capabilities, allowing us to offer even more precise and customised foam parts.

Jordan’s story is proof of the exciting future of foam engineering at Kewell Converters. With fresh talent like him bringing new ideas and blending them with traditional foam conversion techniques, we continue to push the boundaries of what’s possible in foam fabrication. His journey from the prep team to production engineer shows the opportunities available for those who are eager to learn, adapt, and innovate in this ever-evolving industry.

If you’re looking for high-quality foam parts or want to learn more about our cutting-edge foam fabrication techniques, get in touch with us today. Whether you need precision foam shapes or custom foam solutions, our expert team is here to help!

Meta description: Meet Jordan, a rising star in foam engineering at Kewell Converters. Discover how his passion for efficiency and precision is shaping the future of foam fabrication

6th February 2026

Read more >

16th December 2025

Read more >

11th November 2025

Read more >