Precision under pressure: custom foam solutions for MOD applications

Delivering defence-grade foam parts

Background

At Kewell Converters, we’re proud to be recognised as one of the UK’s leading foam converters, delivering bespoke foam solutions across a wide range of industries, from automotive and aerospace to defence and military packaging. Our specialist team has decades of experience in providing high-quality, precision-engineered foam parts that meet even the most complex requirements.

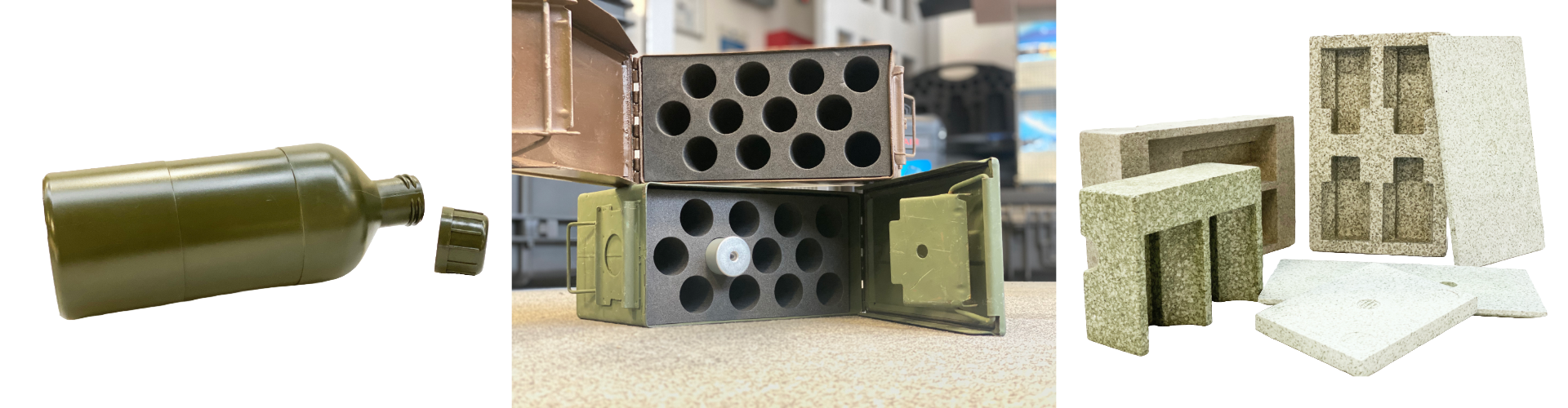

Recently, we were approached by an established supplier to navies across the globe—to help develop a highly specialised product for the Ministry of Defence (MoD). The task? To create a removable capture container for active defence hardware, which included a metal panel cover with a precision-cut foam insert bonded on the underside to capture the required parts during live service —an uncommon and technically demanding combination that required meticulous planning, sourcing, and production.

The challenge

This wasn’t the first time we had worked on defence-related projects, but this request stood out due to the rare requirement of bonding foam parts to a metal component. While we had completed similar projects in the past, the combination of materials, compliance demands, and the scale of the job presented a unique challenge.

Several factors were non-negotiable:

- Use of defence-approved materials, including military grade foam

- Full traceability across the supply chain

- Consistent supply on a scheduled basis

- A scalable, repeatable process that could be rolled out again as required

- Above all, absolute confidence in the foam’s performance and protective capabilities

Kewell Converter’s ability to design and manufacture custom-made MoD-approved foam packaging made us a natural choice for the project. Take a further look at our blog to learn more about our proud legacy with the defence and military industry.

The solution

Led by Geoff and Neil from our manufacturing team, the project began with detailed product testing to ensure that the foam met the MoD’s strict safety and performance requirements. This involved submitting extensive documentation and quality assurance paperwork—a process that normally takes a few days but extended over several months due to the complexity of the supply chain.

The raw materials specified by the customer were LD45 Plastazote for the foam insert and aluminum for the cover panel. Plastazote is a high-quality material known for its strength, durability, and protective properties. It was required to meet military specification Def Stan 81-116, Grade C, Type QX. The cover panel was made from an Aluminium alloy, cut to include access features, and anodized to a military specification, before being primed and painted in NATO Green (BS381C), but only on one surface.

This specialised military-grade parts needed to be sourced, tested, and approved before any manufacturing could commence.

Kewell Converters managed four separate suppliers for the project, sourcing the metal, paint, and foam locally, ensuring every element met MoD standards. With a concept drawing already supplied, our in-house design team created precision cutting programmes and issued a works order to the factory floor.

The production process was multi-stage and highly detailed involving:

- Foam splitting and laminating

- Use of our adhesive machine

- Die stamping with our press machine

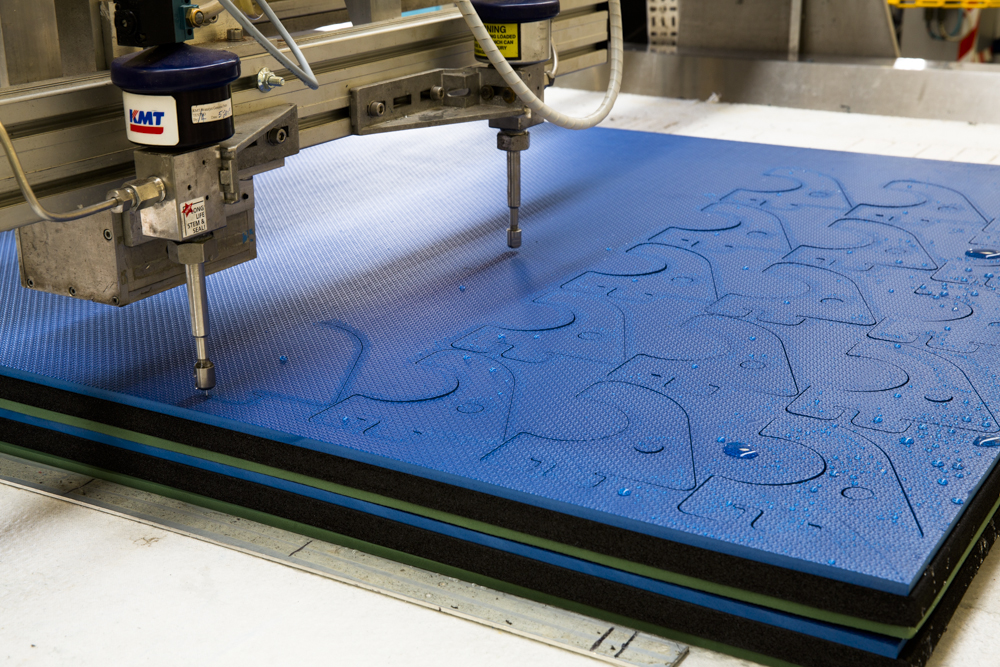

- Precision CNC routing to ensure exact dimensions

- Final assembly of foam onto the metal lids

Each part required a full week of combined labour, and the initial batch included over 100 units. In the following month, we successfully ramped up production meeting the customer’s exact specifications and schedule.

The results

From testing and compliance through to fabrication and delivery, the project ran smoothly thanks to the careful coordination and expertise of our team. The customer was extremely pleased with the quality and repeatability of the final product. Most importantly, the components provided robust product protection and met all MoD requirements.

This project is a prime example of how Kewell Converters combines technical know-how, specialist sourcing, and precise foam fabrication to deliver complex, high-value solutions for the defence sector. Whether it’s military foam solutions, custom foam defence components, or repeatable foam conversion processes, we deliver reliability and results at every stage.

Looking for defence-grade foam expertise you can rely on?

Whether you need custom-made MoD-approved foam packaging, military grade foam, or repeatable, high-spec foam solutions for defence and aerospace applications, Kewell Converters has the experience and capability to deliver. From concept to production, we specialise in precision-engineered foam parts that meet the most demanding standards.