Medical and Hygiene Foam

Custom-engineered foam products for critical care and high-compliance sectors

At Kewell Converters, we don’t just convert foam – we engineer solutions. Our medical and hygiene foam parts are manufactured to meet rigorous tolerances and are backed by our in-house design and foam fabrication expertise. We’re here to solve complex problems, reduce your supplier burden and help you bring innovative, compliant products to market with confidence.

Engineered foam for medical & hygiene applications

Whether you’re sourcing custom foam for a diagnostic tool, a wound dressing, or orthotic support, Kewell Converters has the experience, materials and capabilities to deliver.

Our clients include leading healthcare manufacturers and suppliers, who rely on us to deliver consistent, high-quality foam solutions that are fit for purpose, certified where required, and ready for integration into larger systems or devices.

We work with a wide range of medical-grade foams, including PLASTAZOTE, the most cited thermoplastic foam in medical literature, known for its biocompatibility, lightweight strength and comfort. These specialty foams are ideal for skin contact and widely used in a variety of applications.

Diagnostic imaging

Foam components designed to be MRI, CT and X-ray transparent (radiolucent), enabling safe and effective positioning of patients without image interference

Orthotic and prosthetic supports

Foam shapes tailored for splints, limb supports, back braces, and cervical collars, offering lightweight comfort, hygiene and structural support

Podiatry

Custom foam insoles and footbeds for conditions such as plantar fasciitis and flat feet, using foams of varying densities to target specific pressure points

Surgical aids and supports

Soft, non-irritant foams used in slings, straps, pads and sleeves for use during and after surgical procedures

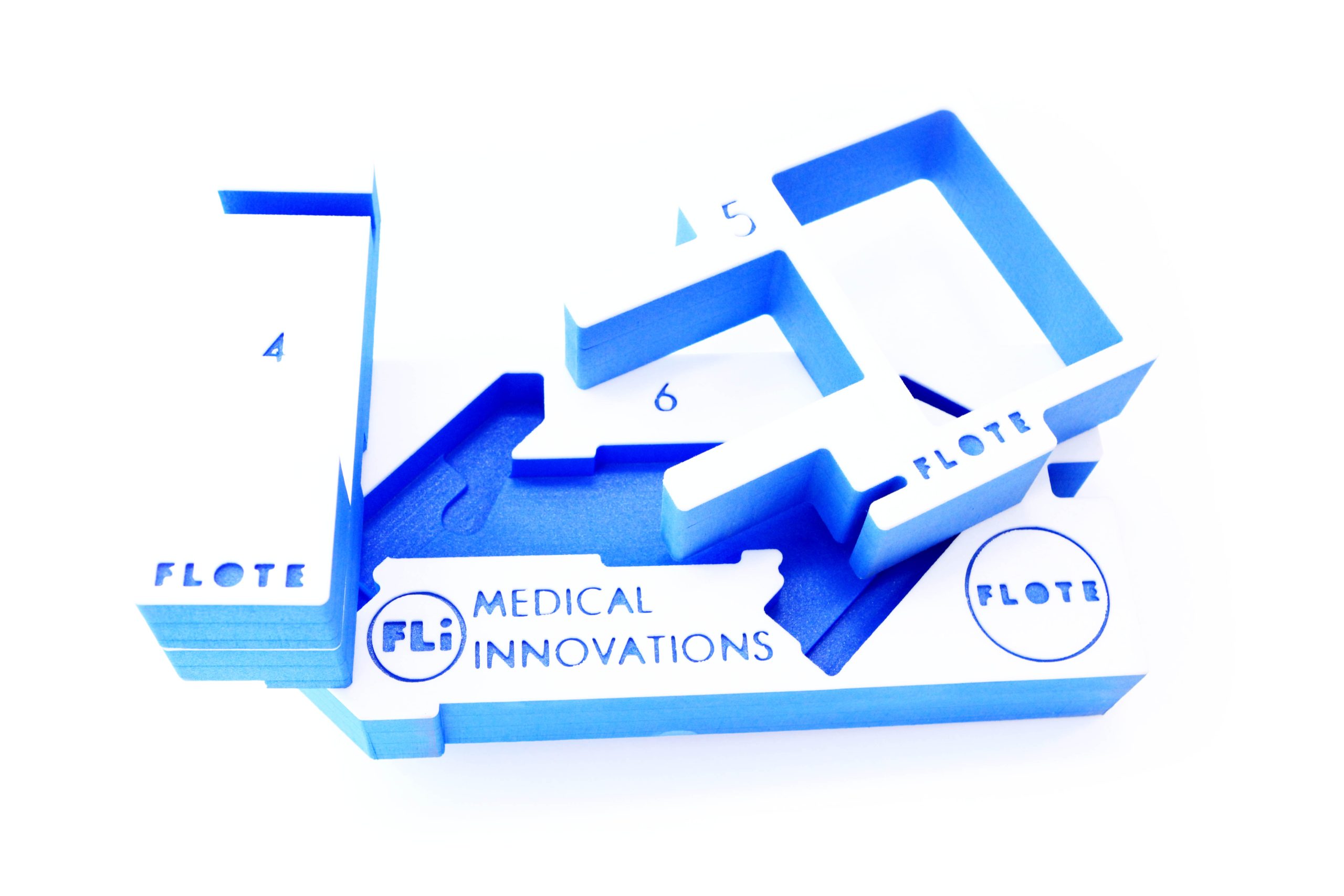

Medical packaging and foam inserts

Protective foam inserts for transporting sensitive instruments and devices, offering a clean, cushioned, and secure environment

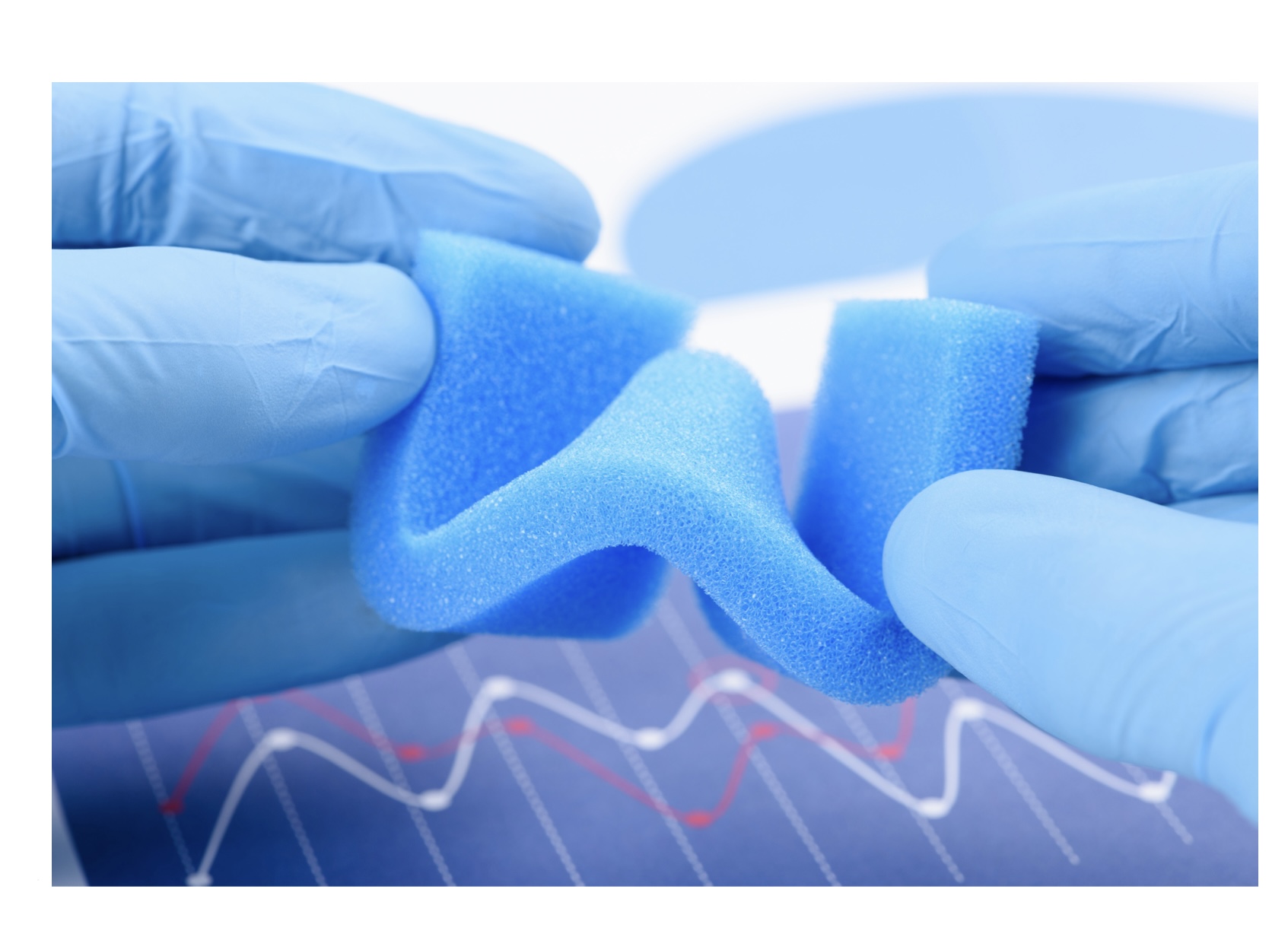

Wound care and dressings

Absorbent foam materials that support healing by maintaining a moist wound environment while cushioning and protecting vulnerable skin

Infection control

Antimicrobial and fluid-resistant foams for products used in hospitals, care homes, dental practices and laboratories, helping reduce cross-contamination risks

Patient comfort solutions

High-quality foam components in mattresses, wheelchair pads, head supports and seating systems that relieve pressure and improve hygiene

Bespoke medical foam solutions

Every project we deliver is tailored to your specific requirements, from foam grade selection to part geometry and cutting tolerances. Our advanced manufacturing techniques include CNC routing, water jet cutting and die-cutting, allowing us to produce foam components to tight tolerances at both prototype and production scale.

When you partner with Kewell Converters, you gain access to our full in-house engineering and CAD design team, enabling you to bring your concepts to life faster, more efficiently, and with less risk.

Whether you’re developing a new healthcare product or refining an existing one, we’ll guide you through the foam selection, prototyping, testing and production process—so your final part is performance-ready and market-compliant.

Why choose Kewell Converters?

At Kewell Converters, foam is a craft. We are the UK’s leading independent foam fabricator, offering:

- Full CAD and engineering support to optimise product design and functionality

- Precision manufacturing of intricate, medical-grade foam parts and foam shapes

- ISO-certified processes and strict quality control for medical and hygiene applications

- Zotefoams approved converter, with deep knowledge of branded and high-quality foam materials

- Proven experience delivering foam for defence, aerospace and life-saving devices

- Capability to manage the full supply chain, reducing your workload and risk

We help you streamline your supply chain while raising product performance and compliance levels, giving you peace of mind and a commercial edge.

Let’s build a better foam solution

If you’re looking for a reliable, expert foam converter who understands your sector, your standards, and your deadlines, you’re in the right place. We’ll work closely with your team to deliver a bespoke medical foam solution that performs.

FAQs

Medical foam is used in a wide range of healthcare products, including orthopaedic supports, prosthetics, diagnostic imaging pads, wound care, and infection control applications.

Yes. We supply medical-grade, hypoallergenic and antimicrobial foams like PLASTAZOTE that are safe for skin contact and widely used in healthcare settings.

Absolutely. As a bespoke foam converter, we provide full CAD support and help with design optimisation, material selection and manufacturing for custom parts.

Whilst we can manufacturer these products, we do not operate clean room manufacturing, which can be a requirement for parts in these applications.

Because we work exclusively with foam. Our experience, machinery and material knowledge are entirely focused on getting the most out of high-quality foam materials to create precise, high-performance solutions.