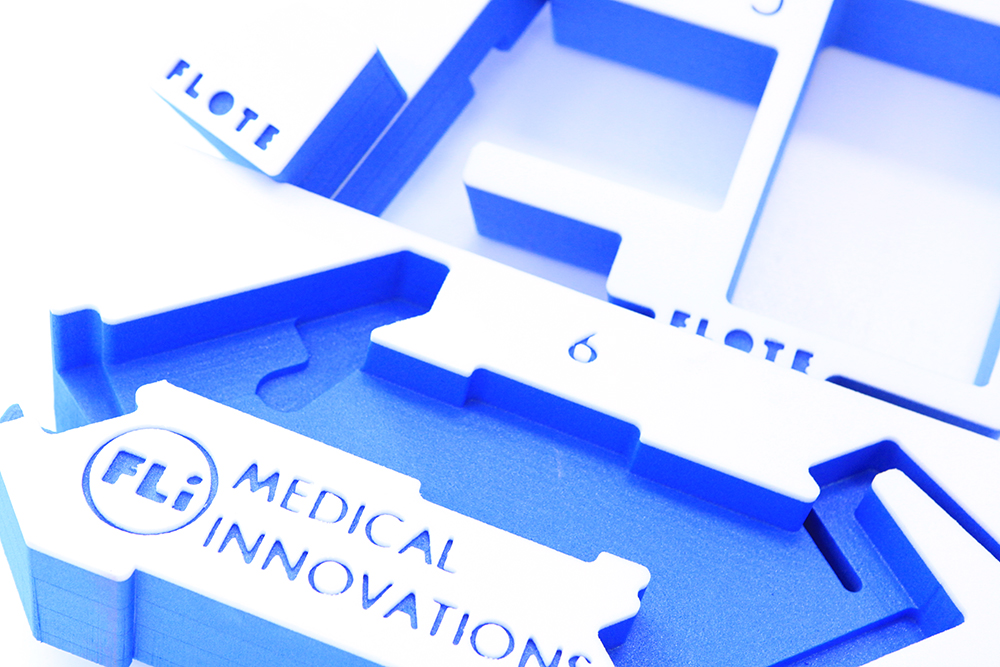

Medical & Healthcare

Specialist foam conversion for medical devices, prosthetics & patient care

For more than 50 years, Kewell Converters has been trusted by leading healthcare and medical device companies to deliver bespoke foam solutions that combine precision engineering with patient comfort and safety. We work exclusively with foam, giving us an unmatched depth of knowledge in how to design, convert and fabricate specialised foam parts that perform consistently in demanding medical environments.

We understand the challenges procurement and supply chain teams face: balancing compliance, cost efficiency and patient safety while reducing the number of suppliers to manage. That’s why we don’t just cut or shape foam. Kewell Converters provides a complete service, from CAD design to sourcing, fabrication and assembly, to streamline your supply chain and deliver ready-to-use engineered foam products.

High-performance medical foam materials

Kewell Converters is one of the UK’s most experienced foam converters of Plastazote®, Evazote® and Supazote®, which are manufactured by Zotefoams. These specialised foams are widely specified in medical literature thanks to their purity, consistency and safety.

Alongside Zotefoams products, we also convert and fabricate a wide range of high-quality foam materials, including:

- Polyethylene (PE) foams, including high-density grades: durable, chemically resistant and water-repellent, making them suitable for orthotic supports, medical trays and protective packaging

- Neoprene and EPDM foams: resistant to oils and disinfectants, commonly used for seals, gaskets and protective padding in medical equipment EVA foam (Ethylene-Vinyl Acetate): lightweight, flexible and shock-absorbent, widely used in podiatric orthoses, inlays and diagnostic footwear

- Polyurethane (PU) foams: available in open cell and closed cell structures, ideal for padding, cushions, protective linings and acoustic control in medical equipment

Reticulated foams: open cell structures with excellent airflow, often used in air filters, hydrotherapy systems and ventilator components

Bespoke foam solutions for healthcare applications

Every component is custom-designed to specification ensuring procurement teams receive exactly the foam part needed without compromise.

Our team of specialist foam engineers designs and manufactures components across a wide range of healthcare products, including:

Prosthetics

Lightweight cosmetic covers and liners for upper and lower limb devices, offering comfort without compromising durability

Podiatrics

Insoles, inlays and orthoses tailored to conditions such as flat feet, bunions or fallen arches. By combining different densities of Azote foams (Plastazote®, Evazote®, Supazote®, & Ecozote®), we create solutions that balance shock absorption with firm support.

Orthoses

Cervical collars, spinal supports, braces, immobilisers and splints manufactured from high-density Plastazote® for rigidity with reduced weight

Medical accessories

Foam used in hydrotherapy equipment, patient positioning devices, helmets, cushions, exercise mats and wheelchair supports, all designed for comfort and hygiene

Case studies

These examples show how Kewell Converters turns technical foam capabilities into practical healthcare solutions that improve patient outcomes and add enormous value for our customers.

Why partner with Kewell Converters?

- 50 years of specialist experience as the UK’s leading independent foam converter

- End-to-end service – design, engineering, sourcing, fabrication and finishing

- Expert team of foam engineers ensuring precision, repeatability and compliance

- Streamlined supply chain – fewer suppliers to manage, faster delivery of finished parts

When it comes to medical foam solutions, our expertise helps procurement teams secure reliable supply, engineers get the performance they need, and patients benefit from safe, comfortable and durable products.

Let’s work together

Whether you need bespoke foam parts, engineered protective foam inserts or ongoing supply of high-quality foam materials, Kewell Converters can deliver the right solution for your project.

Get in touch with our team today to discuss your medical and healthcare foam requirements.

FAQs

We work with Plastazote®, Evazote®, Supazote®, Zotek ®, Ecozote®, EVA, PU, PE, neoprene and reticulated foams, all chosen for their safety, durability and consistency.

Both. We provide fully finished, ready-to-use components as well as cut parts, helping reduce supplier management and streamline your supply chain.

Yes. Our medical-grade foams are non-toxic, hypoallergenic and latex-free, making them safe for prosthetics, orthotics and podiatric devices.

We use CNC routing, water jet cutting and thermoforming to deliver complex shapes and tight tolerances with repeatable quality.