High Temperature Foam Applications

Bespoke foam solutions for extreme environments and demanding industries

At Kewell Converters, we specialise in delivering high-quality, bespoke foam solutions for industries where safety, durability and precision are non-negotiable. With over 50 years of expertise in foam conversion we provide engineered foam parts that perform in the harshest of conditions.

We provide complete foam engineering services, from CAD design to sourcing and production, so you can reduce supplier complexity and achieve the highest standards of performance.

What is high temperature foam?

High temperature foam refers to specialised foam materials designed to resist extreme heat, flames, and thermal stress. These include fire-rated foam and Class O foam, which meet rigorous safety certifications and retain structural integrity even in high-temperature environments. At Kewell Converters, we work with a variety of branded foams, including Zotefoams, and offer both lightweight and durable options tailored to your exact requirements.

These specialty foams are essential in industries where thermal insulation, fire retardancy, and material longevity are critical. Applications range from aerospace insulation and electrical enclosures to military-grade equipment housing and protective foam inserts for transport or storage.

Our heat resistant foam products

Fire rated foam

Designed to meet stringent fire safety standards, our fire rated foams are ideal for environments where flame retardancy and low smoke emission are critical.

Key benefits:

- Meets industry fire-resistance certifications

- Reduces flame spread and smoke development

- Also offers cushioning, insulation, and acoustic control

- Customisable in density, thickness, and form

- Eco-friendly variants available on request

Common uses:

- Aerospace cabin components (seats, wall panels)

- Public transport interiors

- Construction insulation and fireproofing

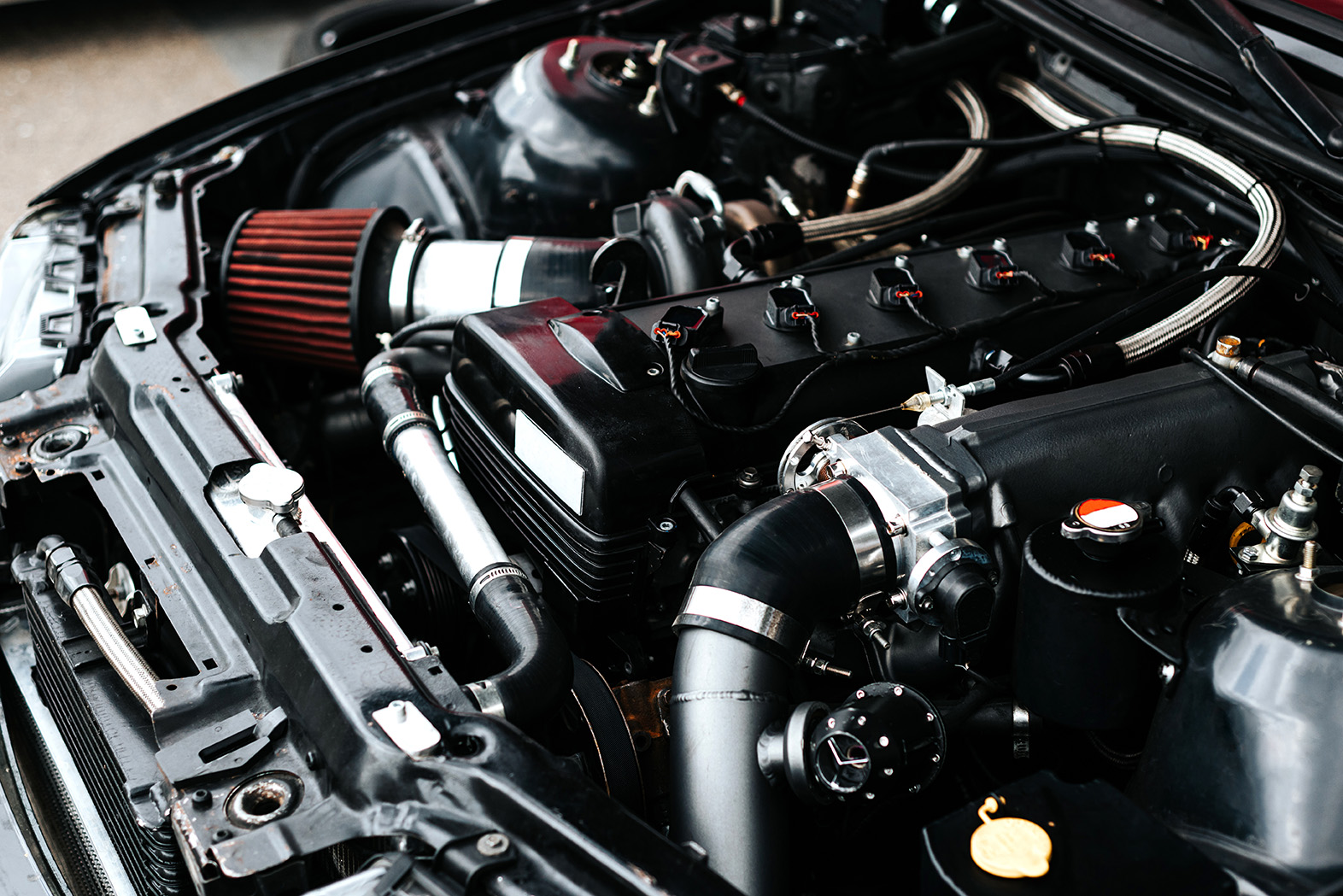

- Automotive interiors and safety padding

High temperature Class O Foam

Our Class O foam is the gold standard in thermal and fire resistance, ideal for applications where temperatures soar and materials must endure.

Key benefits:

- Rated Class O under UK Building Regulations

- Maintains structural integrity under extreme heat

- Available in sheets, rolls, or custom-cut foam shapes

- Long-lasting, durable and crack-resistant

Common uses:

- Aerospace insulation and linings

- Military-grade casings and control panels

- Firewall protection in vehicles

- Heat shielding in industrial equipment

- Electrical and telecoms enclosures

Why choose Kewell Converters for high temperature foam solutions?

50 years of foam-only expertise

We’re the UK’s longest-established independent foam converter focused exclusively on foam. We focus solely on foam and have done so for over five decades.

In-house engineering team & full CAD design

Our experienced engineering team offers full CAD support as standard. This ensures every custom foam part is designed for optimal performance, manufacturability, and cost-effectiveness — minimising waste and maximising precision.

End-to-end supply chain support

From material selection to part production, we take the pressure off your team by managing the entire process. We liaise directly with component suppliers, provide design input, and produce bespoke foam solutions — reducing your supplier burden and project complexity.

Application-specific solutions

Whether it’s Class O foam for fire barriers in electrical enclosures or fire retardant foam for seating and panels in military aircraft, we’ll work with your team to develop a solution that ticks every box: compliance, performance, and value.

Industries we serve

We supply specialised foam and custom foam parts to some of the most demanding sectors, including:

View our Industries

Military & defence

Lightweight, protective foam components for transport, communications and equipment

Aerospace & aviation

Flame-resistant and thermally stable foam for aircraft interiors and insulation

Industrial manufacturing

Foam seals, gaskets, panels and inserts for machinery and production environments

Construction

Class O fire-resistant foam for safe insulation and fireproofing

Transport & automotive

High-performance foam sponges and inserts for seating and insulation

Get started with Kewell Converters

Ready to specify high temperature foam for your next project? Let’s help you design a solution that meets your technical, safety, and procurement needs — all from one trusted UK-based partner.

FAQs

Class O foam is the highest classification for fire resistance under UK building regulations. It’s ideal for any environment where enhanced flame and smoke protection is critical.

Yes, all foam parts, including sheets, inserts, gaskets, or shapes, can be tailored in terms of thickness, density, and form. We offer complete foam conversion and foam fabrication services.

These high temperature application foams are used in aerospace, defence, automotive, and construction industries for protective foam, insulation, and fireproofing components.

They offer enhanced durability, thermal stability, and fire performance, making them suitable for extreme environments that traditional foam materials cannot withstand.