Foam engineered for life

Bespoke foam solutions, engineered for precision

Welcome to Kewell Converters, where bespoke foam conversion and foam fabrication are at the heart of everything we do. With over 50 years of exclusive experience working with foam materials, we’re the UK’s most experienced independent foam converter—trusted by procurement teams and engineers in the aerospace, military, defence, and industrial sectors.

We don’t just manufacture components—we solve problems. Our expert engineering team, paired with our full CAD design service, develops specialised foam solutions that meet exact performance, durability, and environmental requirements. Whether you’re looking for custom foam inserts, protective foam packaging, or engineered foam parts, we deliver with precision, speed and technical confidence.

Uncompromising on quality

Certified to ISO 9001:2015 – because quality can’t be optional

At Kewell Converters, quality is built into every layer of our process. We operate to ISO 9001:2015 standards, ensuring consistently high-quality foam parts and bespoke foam solutions that meet even the strictest tolerances.

This matters most in high-risk sectors like defence and aerospace, where performance must be proven and reliability is non-negotiable. With a team of 30 skilled professionals and an advanced production facility, we guarantee attention to detail, accountability, and dependable delivery across every project.

Quality at Kewell Converters

We have relied on Kewell Converters to accurately translate quite complex drawings for more than a decade. We would recommend them for difficult work.

Quick turnaround of samples and advice on feasibility issues, quality of products supplied usually to the standard expected or above, and expectations met in terms of lead times.

Flexible with improving designs and working with sometimes inadequate files, quote turnaround time usually same day and good communication.

Engineered for high performance

Foam that performs under pressure

We understand the demands of extreme environments. That’s why our custom foam components are designed to withstand impact, vibration, temperature extremes, and environmental challenges.

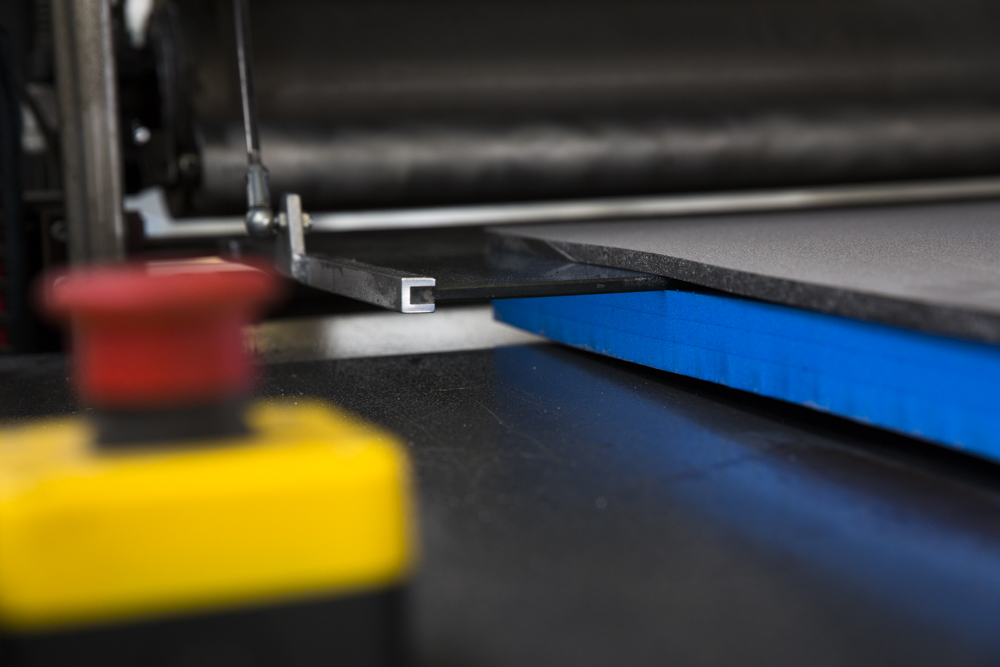

Using advanced foam fabrication techniques and the latest CNC machinery, we manufacture complex foam parts to precise tolerances – whether it’s a lightweight foam panel, foam gasket, strip, or protective insert. Our expertise in specialty foams, including Zotefoams and other branded foams, enables us to match the right material to your performance needs.

Innovation that solves problems

Investing in better outcomes for our customers

Innovation is more than a buzzword for us — it’s how we bring ideas to life. From integrating advanced CAD and CNC systems to exploring the latest foam fabrication techniques, we’re constantly evolving to serve the changing needs of our customers.

Our design-led approach means we collaborate early in the process, offering design for manufacturing guidance and prototyping to get your solution right first time.

Discover how our innovative thinking has helped customers in your sector on our case studies page.

Ready to start your foam project?

Let’s talk. Whether you’re looking for bespoke foam parts, a long-term partner for foam fabrication, or a team that can manage the whole supply chain for you, Kewell Converters is ready to help.

Contact us today or send an enquiry – and find out how we can add value to your next project.

16th December 2025

How foam is quietly powering the next era of advanced engineering

Discover how engineered foam is becoming essential in advanced engineering. Explore 2026 trends in foam conversion, material performance, thermal management, quality, and emerging applications across EVs, aerospace, defence, electronics and manufacturing.

Read more >

11th November 2025

K Show 2025 Insights: Innovation, Sustainability and the Future of Engineered Foam Solutions

Exploring the key themes shaping the plastics and foam industry

Read more >

14th October 2025

Reflections from 11 Downing Street: The Future of British Manufacturing

Celebrating collaboration and UK manufacturing excellence

Read more >