30th April 2024

Job Title: Sales Administrator

Read more >

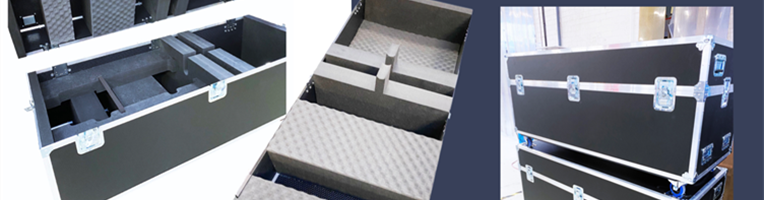

The critical task of transporting high-value medical units by air requires exceptional care. Kewell Converters Ltd (KCL) leads in this field, crafting bespoke foam interiors for flight cases used by a global leading medical equipment manufacturer. This article explores the expertise KCL brings to the design and production of these tailored foam solutions, the collaboration with case brands, and their dedication to customer service.

KCL’s journey with a client begins with a concept, often a brief outline provided for the medical equipment needing protection. This is where KCL’s expertise shines, transforming these initial ideas into a custom-fit protective foam interior, ensuring each medical device is secured against the challenges of air transportation.

KCL understands that Original Equipment Manufacturers (OEMs) may have varying order requirements. They offer adaptable services whether dealing with Minimum Order Quantities (MOQs) or Minimum Order Charges (MOCs), guaranteeing that each project, regardless of size, receives meticulous attention to detail.

At KCL, the process is honed to provide the most economical and high-grade case solutions. Their thorough design, material selection, and precision manufacturing processes are tailored to meet the exacting demands of the medical sector, ensuring every case is fit for purpose.

KCL’s innovative approach to designing foam inserts is evident in their attention to the specific needs of air-freighted medical equipment. The company extends its innovation to assembling and outfitting cases, so they arrive ready for use, streamlining efficiency for OEMs.

Beyond foam inserts, KCL offers a complete service that encompasses the sourcing and supplying of a diverse range of case options. This ensures clients can select the optimal packaging solution for their valuable equipment, with a choice from the best suppliers in the market.

KCL’s commitment to quality assurance means each case and insert is rigorously checked to maintain the company’s high standards. This meticulous quality control gives clients confidence in the protection and longevity of their medical equipment cases.

KCL prides itself on offering complete assembly and fit-out services, providing OEMs with the convenience of having their products packed and dispatched from one location. This comprehensive service model is designed to streamline the OEM’s operations and enhance overall productivity.

KCL’s range of cases caters to any need, from lightweight to heavy-duty options, ensuring the right fit for the job. They take pride in supplying cases that meet the client’s budgetary and performance specifications without compromise.

While KCL’s proficiency in the medical sector is paramount, their expertise is not confined to it. They also serve various industrial and commercial markets, adapting their solutions to meet different environmental and product-specific needs.

KCL’s adherence to innovation and their broad product offering affirm their position as a leading provider of custom foam interiors for protective cases. Their role in the safe and efficient transportation of medical equipment is a testament to their impact on global health services.

For more details on KCL’s bespoke foam solutions and services, or to discuss specific requirements, customers are encouraged to contact us. KCL is dedicated to building robust client relationships and delivering outstanding service and products.