18th April 2024

Celebrating Creativity and Innovation in Foam at Kewell Converters

Celebrating Creativity and Innovation in Foam at Kewell Converters

Read more >

18th April 2024

Celebrating Creativity and Innovation in Foam at Kewell Converters

Read more >

18th April 2024

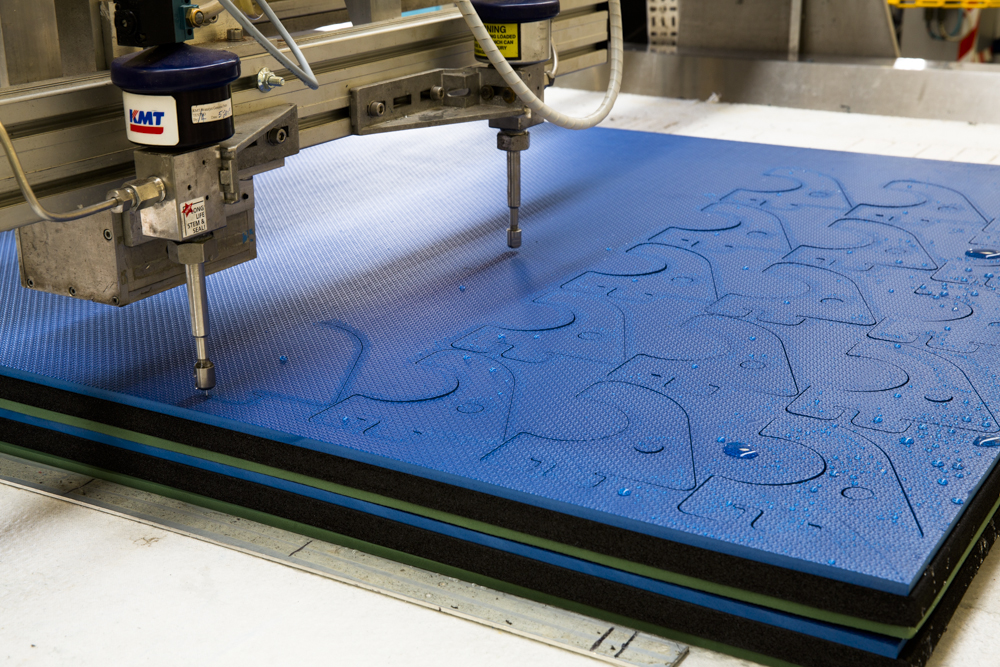

Precision Meets Innovation: Water-Jet Cutting at Kewell Converters

Read more >

21st March 2024

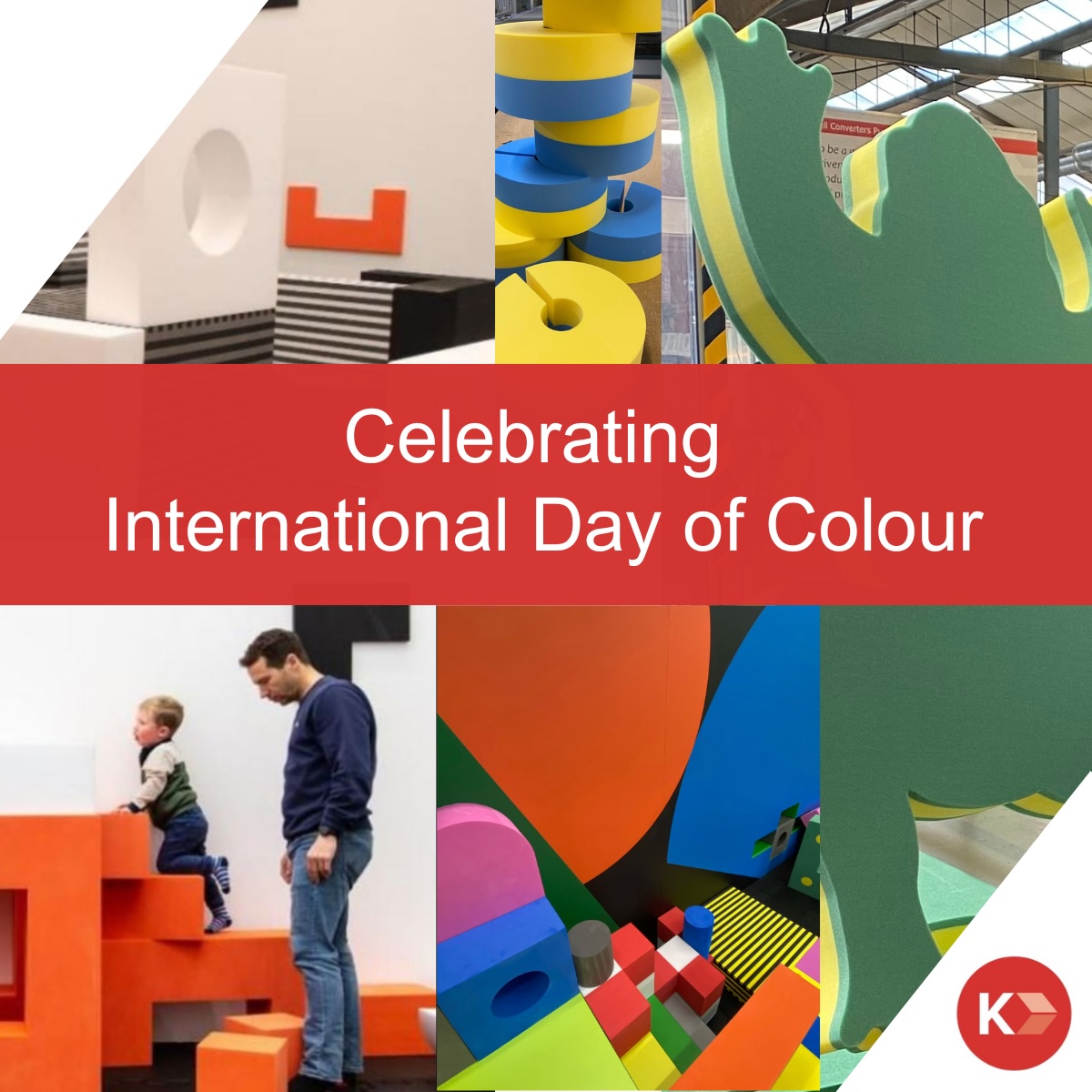

The Vibrant Role of Colour in Foam Products on International Day of Colour

Read more >

21st March 2024

The Intricacies of Compression Moulding: Shaping Innovations in Manufacturing

Read more >

7th March 2024

Strength in Diversity: Celebrating the Women of Kewell Converters

Read more >

27th February 2024

Supporting Selsdon Junior Lionesses

Read more >

27th February 2024

World Engineering Day Insights with our MD

Read more >

6th February 2024

We are seeking a highly motivated, hardworking Customer Service individual.

Read more >